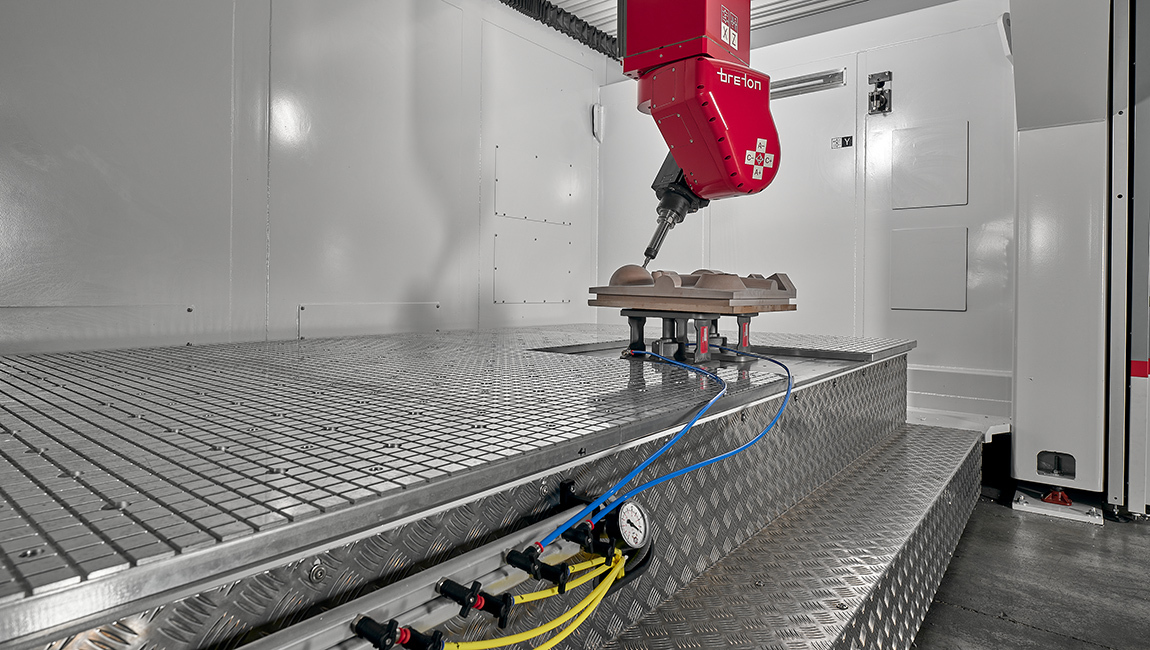

Breton Hawx is delivered preassembled with a prewired electrical cabinet. Once the customer has positioned the machine, only the front housings remain to be fitted. The entire assembly and start-up procedure takes just 5 days: in the first 3 days the machine is unloaded, anchored, and completed, start-up takes place on day 4 while day 5 is reserved for training. Hawx can be easily relocated on the customer's site to accommodate possible changes to the production layout.

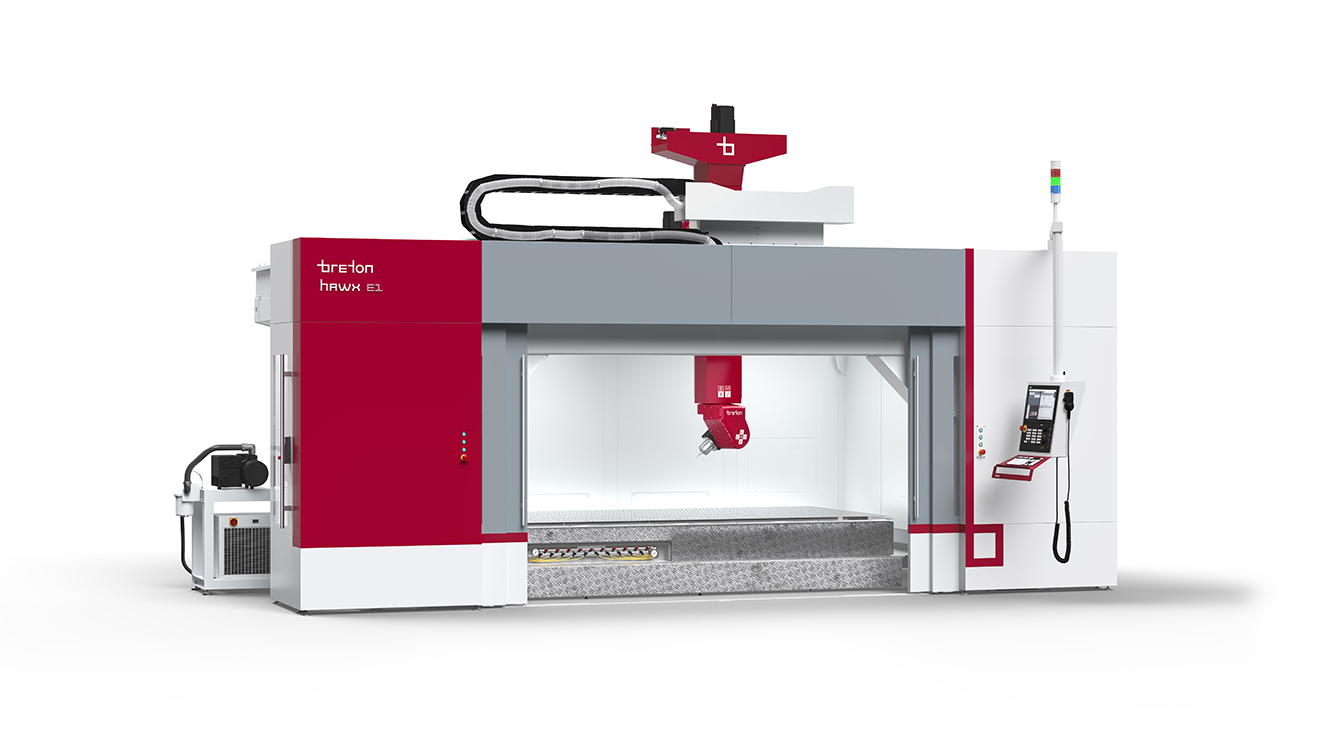

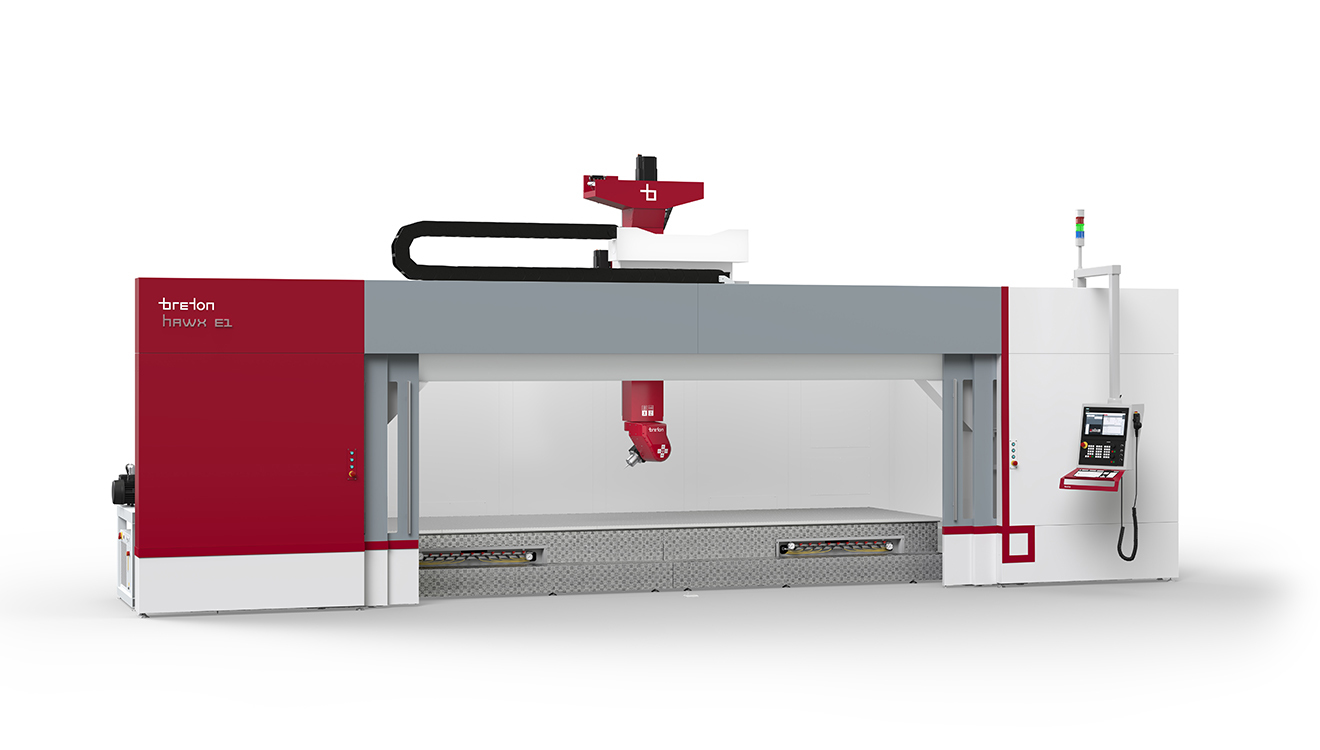

High dynamic 5 Axis vertical machining centre with gantry modular design and expandable configuration

The right combination of robustness and stability makes it ideal for high-speed milling and trimming operations on elements with complex three-dimensional shapes made of light alloys, polymers and resins or composite materials.

Breton Hawx

Reasons why

Class-leading robustness and repeatability

Designed to overcome the common limits of this product category: reduced robustness and poor repeatability over time.

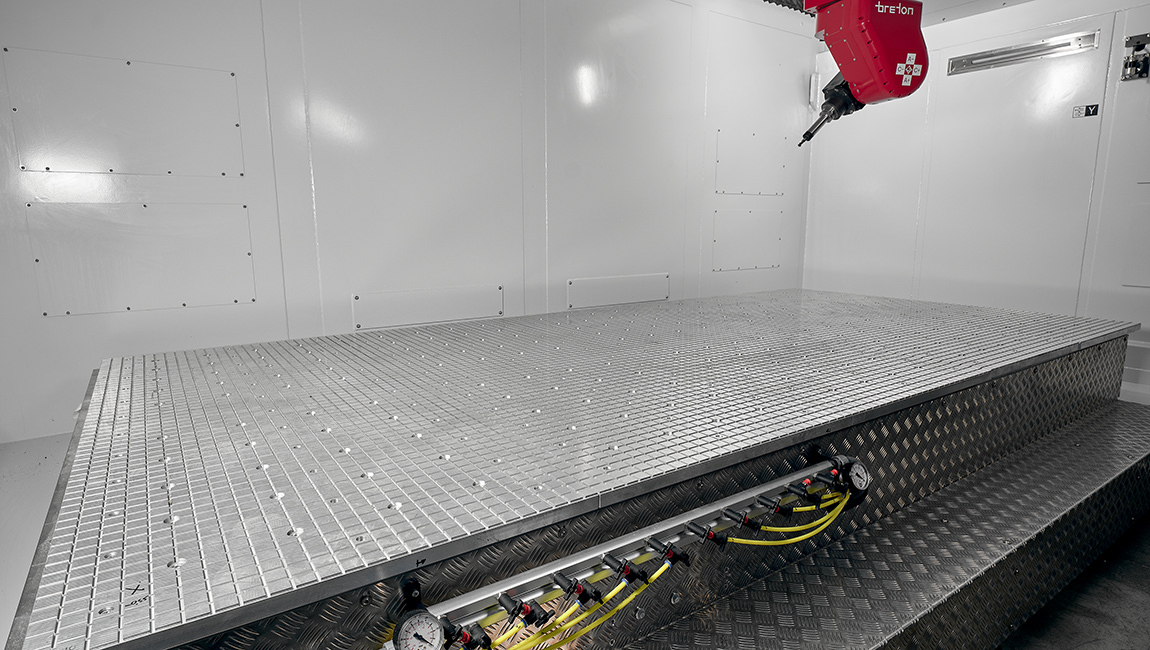

Thanks to its optimised design, Breton Hawx is not only more rigid and stable but also guarantees an excellent size-towork area ratio.

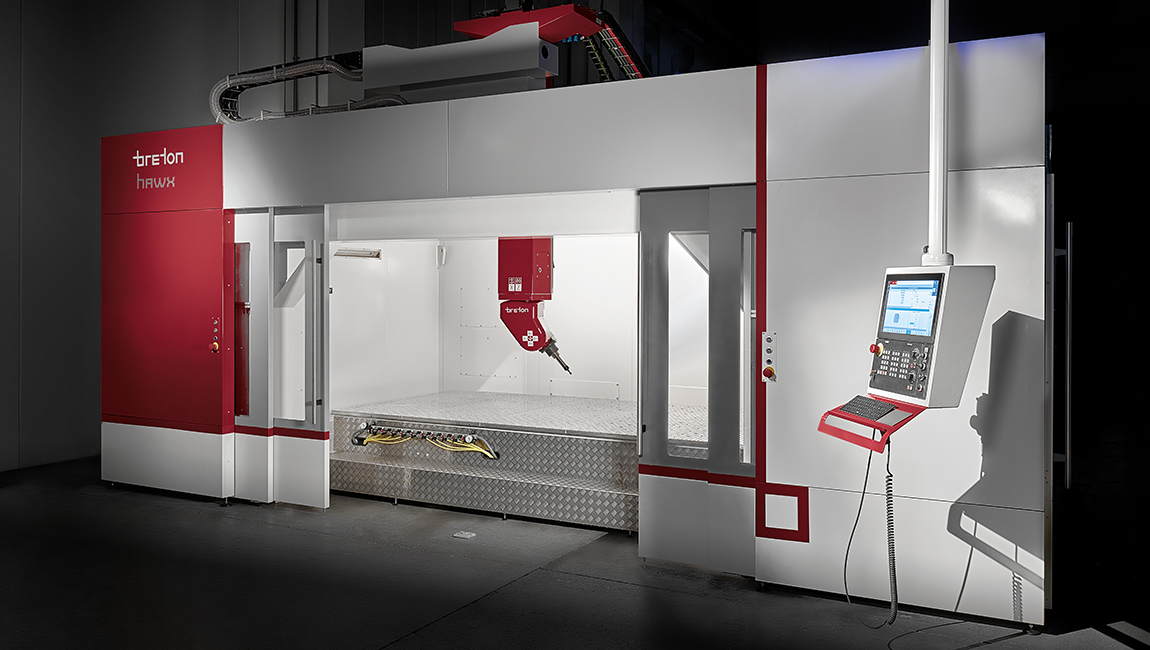

It is easily integrated into all production environments, it’s delivered already assembled and tested; it does not require special foundations and has minimal commissioning times.

The Hawx E1 is built using a selfsupporting monolithic structure, which is one of the main characteristics of the machine, making it robust and enabling easy handling for delivery and installation.

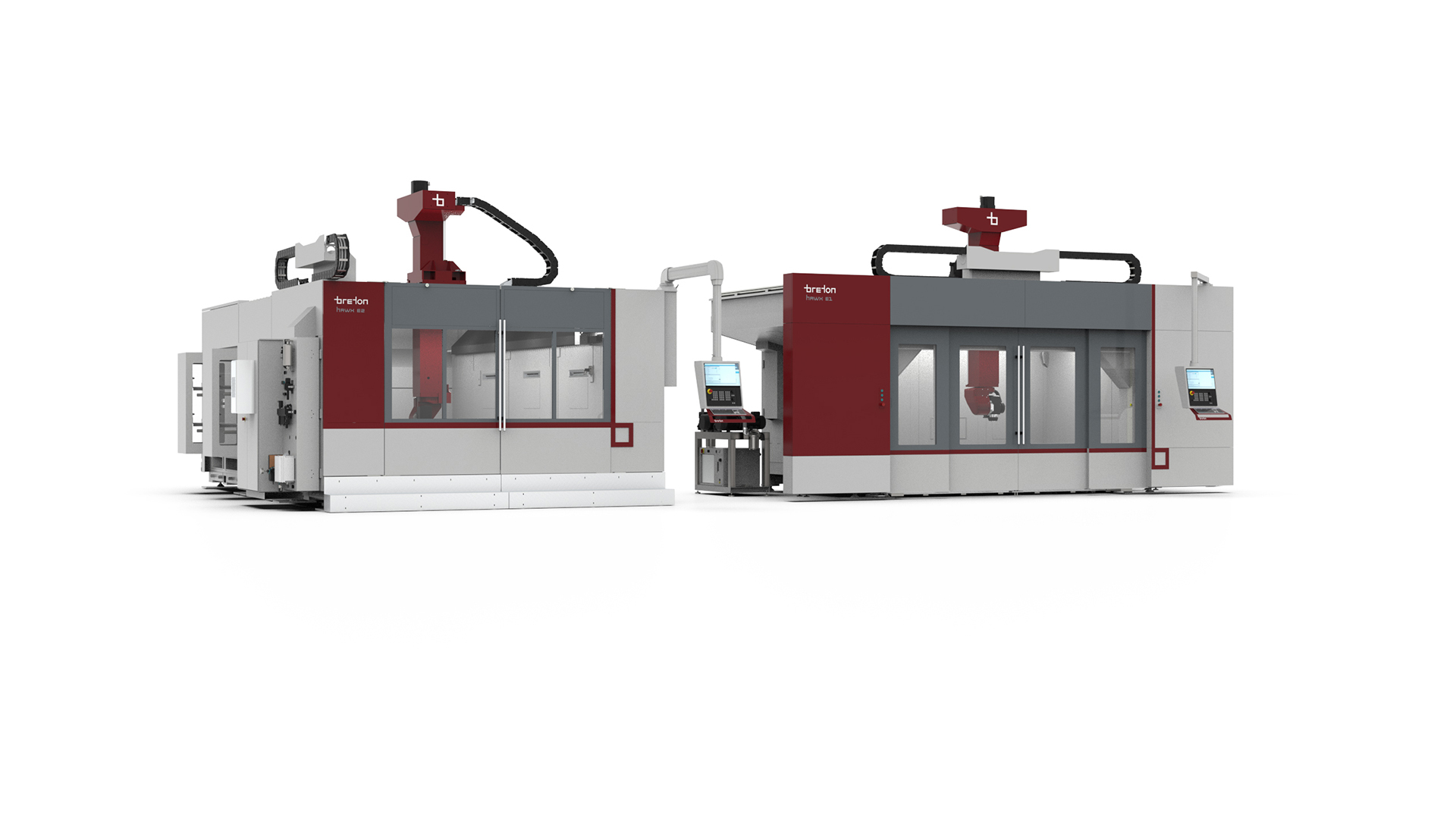

The Hawx E2 foresees a pre-assebled starting module made from a U-shape monoblock structure which is expandable longitudinally using one or more pre arranged and calibrated extra U-shape supporting frames.

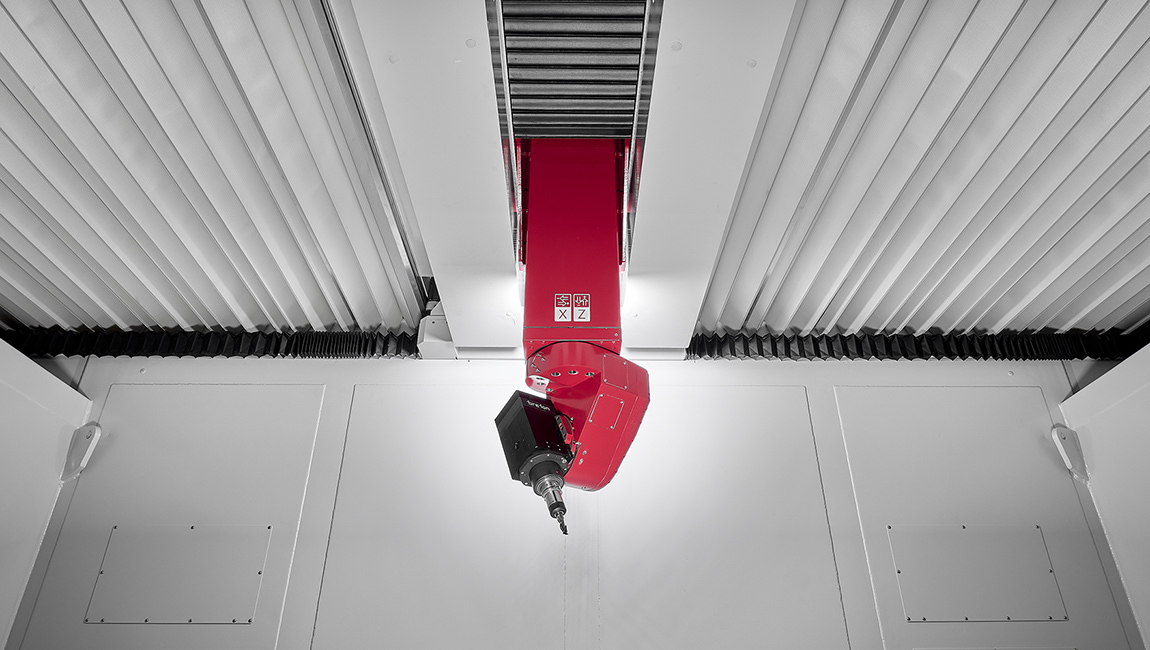

Both versions of the machine are built with a box-in-box architecture that guarantees a significant increase in rigidity of the bridge-ram assembly.

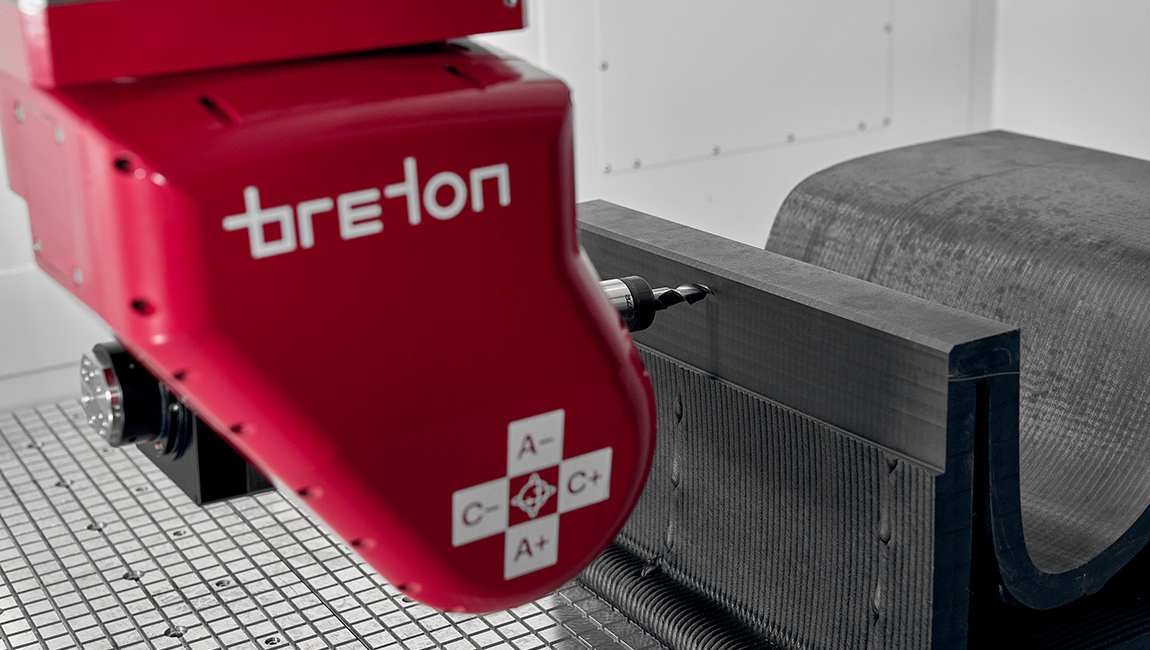

The high strength, characteristic also of the new Hornet head, enables a remarkable increase in material removal performance and accuracy, all with the greatest dynamics.

The innovative offset geometry of the head allows for an outstanding increase of the machinable volumes while minimizing the external footprint of the machine and enabling a considerable accessibility to the workpice on the undercuts.

Materials

Processes

Industries

Technologies

Applications

Numerical control

Technological highlights

Other versions of Breton Hawx

Version comparative table

| Hawx E1 K40 | Hawx E1 K60 | Hawx E2 K18 | Hawx E2 K38 | Hawx E2 K58 | Hawx E2 K78 | |

|---|---|---|---|---|---|---|

"X" axis travel | 4000 mm | 6000 mm | 1800 mm | 3800 mm | 5800 mm | 7800 mm |

"Y" axis travel | 1900 mm | 1900 mm | 2700 mm | 2700 mm | 2700 mm | 2700 mm |

"Z" axis travel | 1300 mm | 1300 mm | 1300 mm | 1300 mm | 1300 mm | 1300 mm |

"X" axis rapid feed rate | 80 m/min | 80 m/min | 70 m/min | 70 m/min | 70 m/min | 70 m/min |

"Y" axis rapid feed rate | 80 m/min | 80 m/min | 70 m/min | 70 m/min | 70 m/min | 70 m/min |

"Z" axis rapid feed rate | 60 m/min | 60 m/min | 60 m/min | 60 m/min | 60 m/min | 60 m/min |

"A" axis travel | -135 - 105 ° | -135 - 105 ° | -135 - 105 ° | -135 - 105 ° | -135 - 105 ° | -135 - 105 ° |

"A" axis rapid speed | 28 rpm | 28 rpm | 28 rpm | 28 rpm | 28 rpm | 28 rpm |

"C" axis travel (RANGE) | -270 - 270 ° | -270 - 270 ° | -270 - 270 ° | -270 - 270 ° | -270 - 270 ° | -270 - 270 ° |

"C" axis rapid speed | 28 rpm | 28 rpm | 28 rpm | 28 rpm | 28 rpm | 28 rpm |

Max. power in S6 | 25 kW | 25 kW | 18 kW | 18 kW | 18 kW | 18 kW |

Max. power in S1 | 22 kW | 22 kW | 15 kW | 15 kW | 15 kW | 15 kW |

Max. torque in S6 | 20 Nm | 20 Nm | 15 Nm | 15 Nm | 15 Nm | 15 Nm |

Max. torque in S1 | 18 Nm | 18 Nm | 12 Nm | 12 Nm | 12 Nm | 12 Nm |

Max. rotation speed | 24000 rpm | 24000 rpm | 24000 rpm | 24000 rpm | 24000 rpm | 24000 rpm |

Tool taper type | HSK-A63 / HSK-F63 | HSK-A63 / HSK-F63 | HSK-A63 / HSK-F63 | HSK-A63 / HSK-F63 | HSK-A63 / HSK-F63 | HSK-A63 / HSK-F63 |