Genya is delivered pre-assembled with prewired electrical cabinet. Once the customer has positioned the machine, only the front housings remain to be fitted. The entire assembly and start-up phase can be completed in 5 days. Genya can be easily relocated on the customer's site to accommodate possible changes to the production layout.

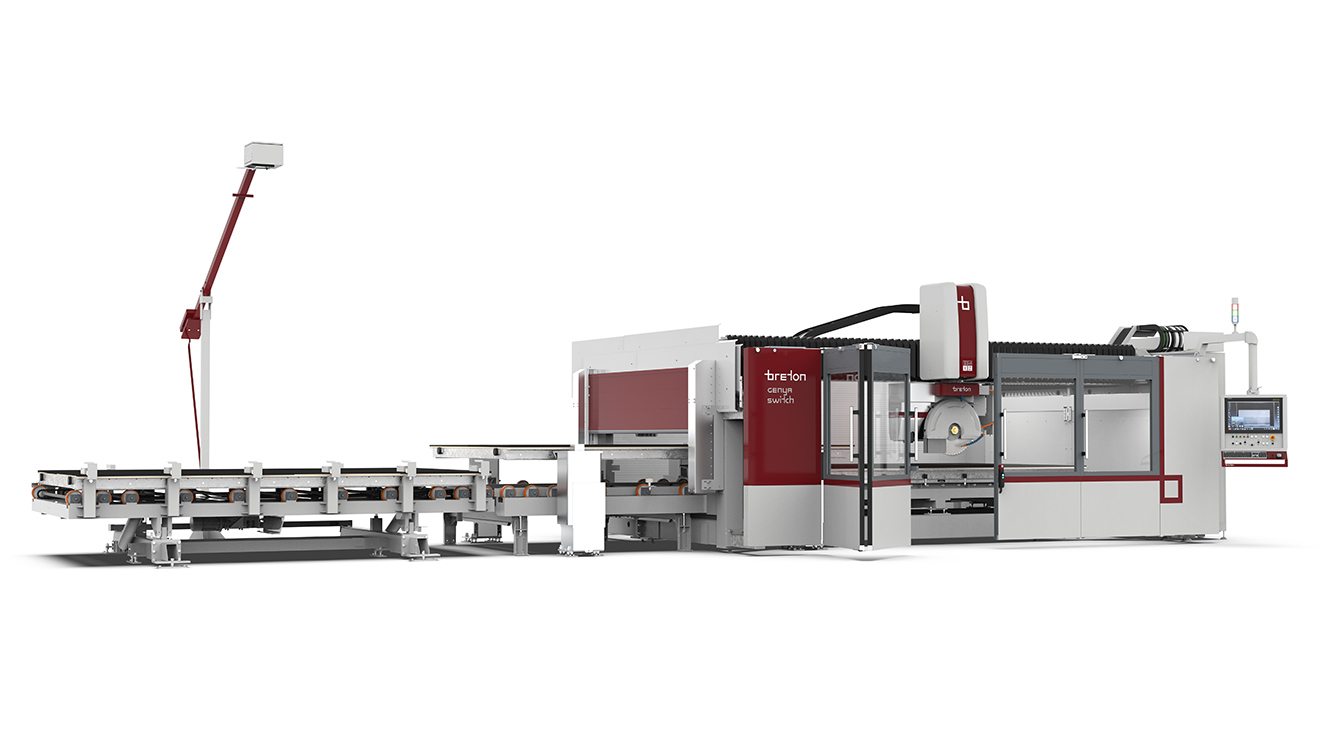

5-axis monobloc disc-type cutting centre

The possibility of having all tools constantly ready for use, together with devices such as vacuum cups on the spindle, bridge camera, and tilting table, make Genya the most efficient machine for the creation of kitchen worktops, vanity tops and claddings.

Breton Genya

Reasons why

The fastest way to make kitchen countertops

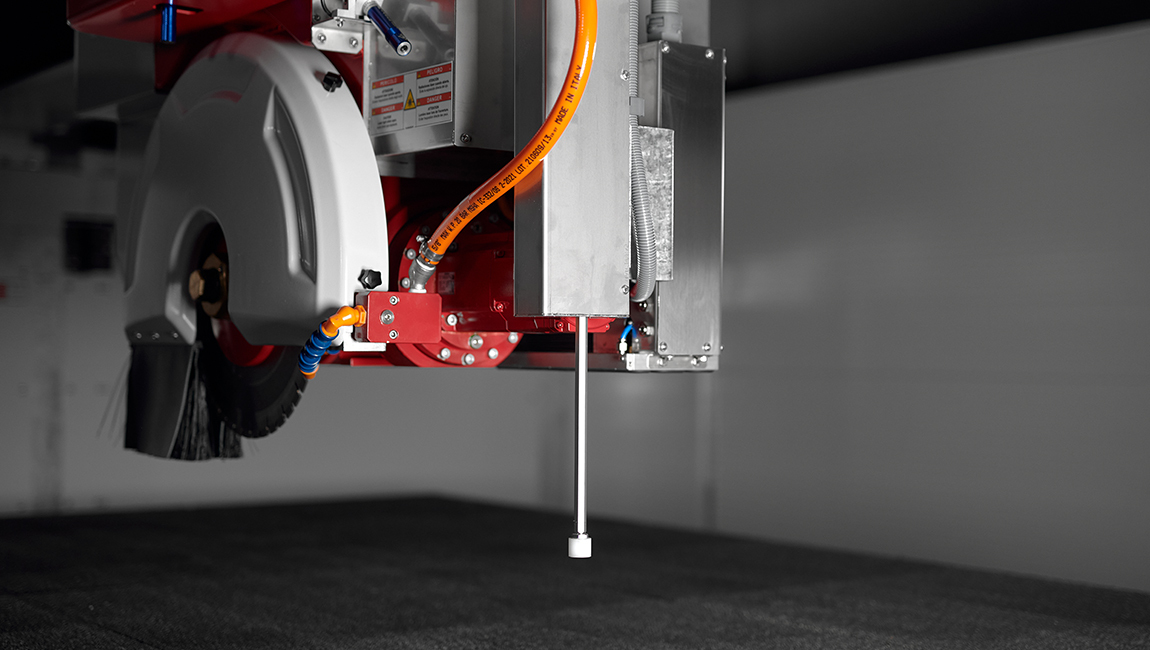

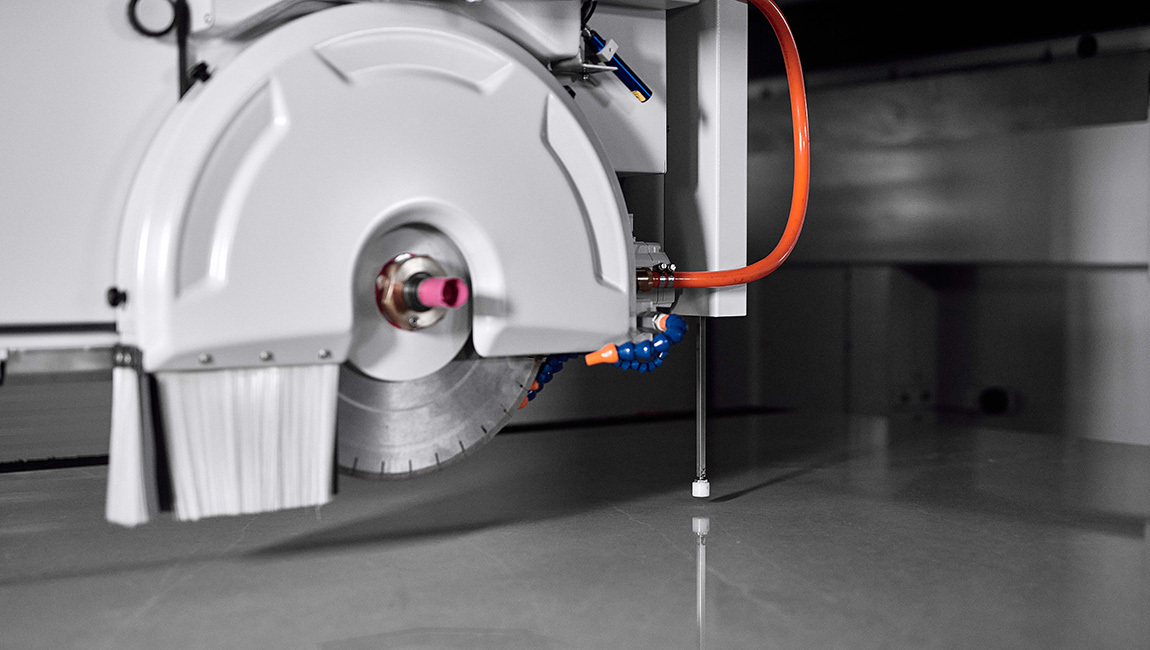

Fully equipped 5-axis disc cutting centre that provides up to 4 different tools installed and ready for use. This generously endowed machine can be fitted with a disc of up to 700 mm in diameter (optional), a core drill bit or mill on the spindle axis, a Rocket Tool with Finger Bit, plus the exclusive and patented Kerasplit for ceramic materials. The tilting table, spindle vacuum cups, bridge camera, and touch probe make operations of loading/unloading, set up and handling of cut pieces far faster and safer, avoiding material wastage and idle times. All this affects productivity, so Genya makes it possible to finish more parts in the same time, thus increasing profits.

Another core characteristic of Genya is reliability. All mechanical and electronic components are top quality, while assembly operations are carried out by Breton's expert technicians, all factors that guarantee long product life with a greatly reduced number of problems.

Materials

Processes

Industries

Finished products

Technologies

Numerical control

Spindle power

Spindle torque

Technological highlights

Other versions of Breton Genya

Version comparative table

| Genya | Genya Switch | Genya Flux | |

|---|---|---|---|

Dimensions of the worktop (width) | 2400 mm | 2400 mm | 2400 mm |

Dimensions of the worktop (length) | 3800 mm | 3800 mm | 4000 mm |

Min. saw blade diameter | 300 mm | 300 mm | 300 mm |

Max. saw blade diameter | 600 mm | 600 mm | 600 mm |

Max. cutting thickness (with Ø 600 mm saw blade) | 185 mm | 185 mm | 185 mm |

"X" axis travel | 3800 mm | 3800 mm | 3800 mm |

"X" axis max. displacement speed | 45000 mm/min | 45000 mm/min | 45000 mm/min |

"Y" axis travel | 2750 mm | 2750 mm | 2750 mm |

"Y" axis max. displacement speed | 45000 mm/min | 45000 mm/min | 45000 mm/min |

"Z" axis travel | 500 mm | 500 mm | 500 mm |

"Z" axis max. displacement speed | 15000 mm/min | 15000 mm/min | 15000 mm/min |

"C" axis rotation | 380 ° | 380 ° | 380 ° |

"A" axis rotation | 0 - 90 ° | 0 - 90 ° | 0 - 90 ° |

Spindle motor power (in S1 duty) | 18 kW | 18 kW | 18 kW |

Spindle motor power (in S6 duty) | 22 kW | 22 kW | 22 kW |

Mass | 6500 kg | 7500 kg | 9500 kg |

Overall dimensions (length) | 5200 mm | 16000 mm | 6150 mm |

Overall dimensions (width) | 6450 mm | 5600 mm | 7200 mm |

Overall dimensions (height) | 3050 mm | 3120 mm | 3050 mm |