Energy Management function for savings in energy usage. Returns the energy recovered during braking to the power grid and/or supplies the energy generated by a motor during braking to another motor during acceleration.

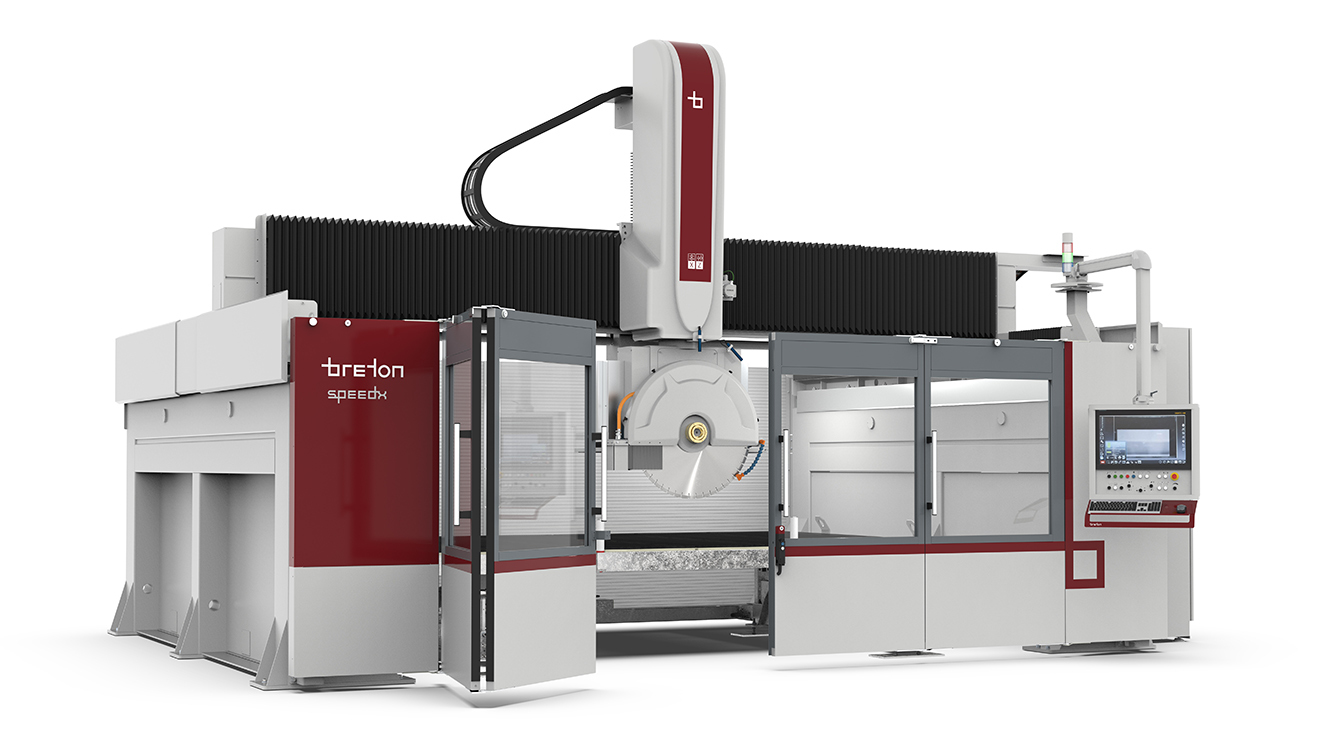

5-axis disc-type cutting centre for high thickness slabs and workpieces

A design developed for robustness and flexibility that exploits the exceptional power and torque available to the full, with Breton's hallmark high mechanical and electronic reliability. All unique features of SpeedX.

Suitable for all work processes, from cutting of high thickness components for building, urban design and funerary art, to creation of kitchen tops, vanity tops, shower trays, various vertical claddings, drilling and shaping.

Breton SpeedX

Reasons why

The ideal solution for machining high thicknesses

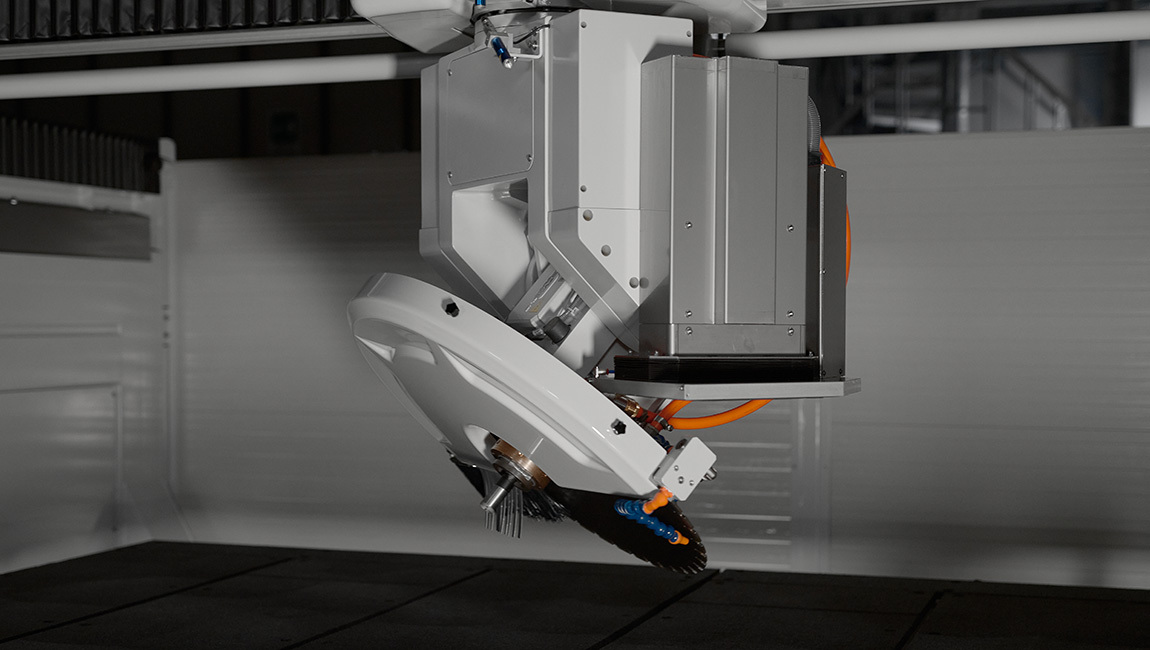

The various SpeedX models differ according to the Z axis stroke and consequently to the diameter of compatible discs.

SpeedX can be equipped with discs from 400 mm to 1400 mm for execution of right-angle cuts up to 750 mm in depth.

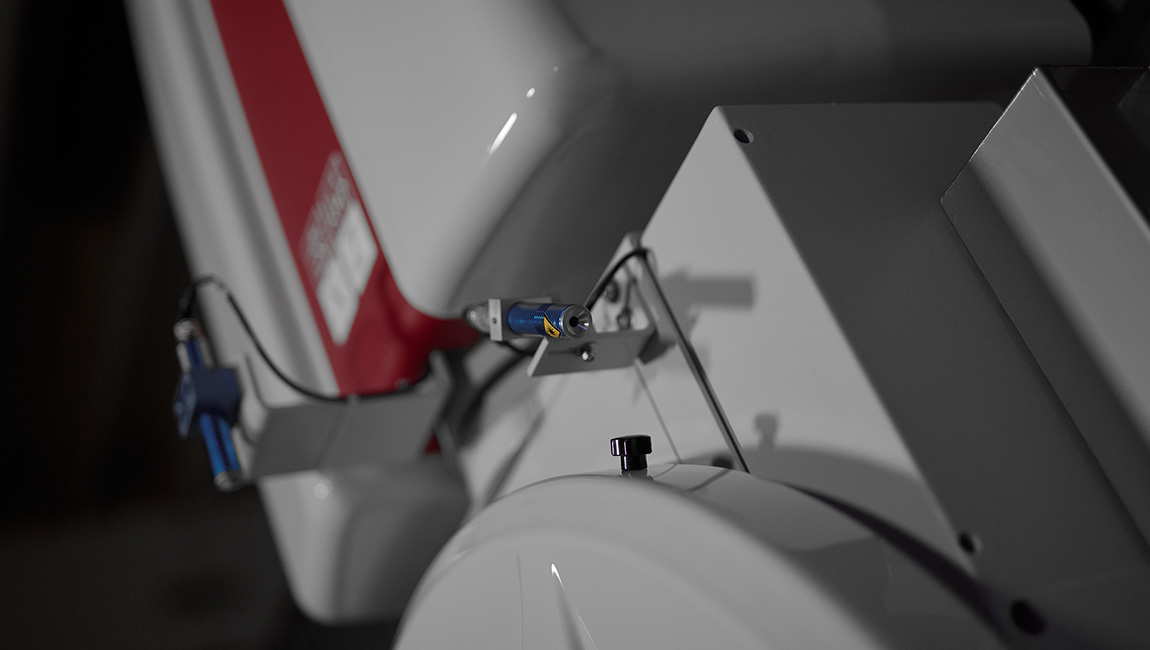

The tilting table, spindle vacuum cups, bridge camera, and touch probe make operations of loading/unloading, set up and handling of cut pieces far faster and safer, reducing material wastage and idle times. All this affects productivity so, thanks to SpeedX, you can process more pieces in the same time, thus increasing revenues.

SpeedX stands out also due to its high reliability. All mechanical and electronic components are top quality, while assembly operations are carried out by Breton's expert technicians, all factors that guarantee long product life with a greatly reduced number of problems.

Materials

Processes

Industries

Finished products

Technologies

Numerical control

Spindle power

Spindle Torque

Technological Highlights

Other versions of Breton SpeedX

Version comparative table

| SpeedX 1000 | SpeedX 1200 | SpeedX 1400 | |

|---|---|---|---|

Dimensions of the worktop (length) | 3800 mm | 3800 mm | 3800 mm |

Dimensions of the worktop (width) | 2400 mm | 2400 mm | 2400 mm |

Min. saw blade diameter | 400 mm | 350 mm | 600 mm |

Max. saw blade diameter | 1000 mm | 1200 mm | 1400 mm |

Max. cutting thickness | 350 mm | 450 mm | 550 mm |

"X" axis travel | 3800 mm | 3800 mm | 4300 mm |

"X" axis max. displacement speed | 40000 mm/min | 40000 mm/min | 40000 mm/min |

"Y" axis travel | 3000 mm | 3400 mm | 3500 mm |

"Y" axis max. displacement speed | 40000 mm/min | 40000 mm/min | 40000 mm/min |

"Z" axis travel | 700 mm | 1200 mm | 1600 mm |

"Z" axis max. displacement speed | 10000 mm/min | 10000 mm/min | 10000 mm/min |

"C" axis rotation | 380 ° | 380 ° | 380 ° |

"A" axis rotation | 0 - 90 ° | 0 - 90 ° | 0 - 90 ° |

Spindle motor power (in S1 duty) | 24 kW | 28 kW | 30 kW |

Spindle motor power (in S6 duty) | 30 kW | 34 kW | 36 kW |

Mass | 6500 kg | 10000 kg | 11000 kg |

Overall dimensions (length) | 5700 mm | 5600 mm | 5600 mm |

Overall dimensions (width) | 7600 mm | 7000 mm | 7800 mm |

Overall dimensions (height) | 4500 mm | 5000 mm | 5800 mm |