The machine features the Energy Management function, which recovers braking energy and returns to the power feeding network.

The special drives employed also make it possible to achieve an internal energy balance whereby the energy generated by a motor during braking can be used for another motor during the acceleration phase.

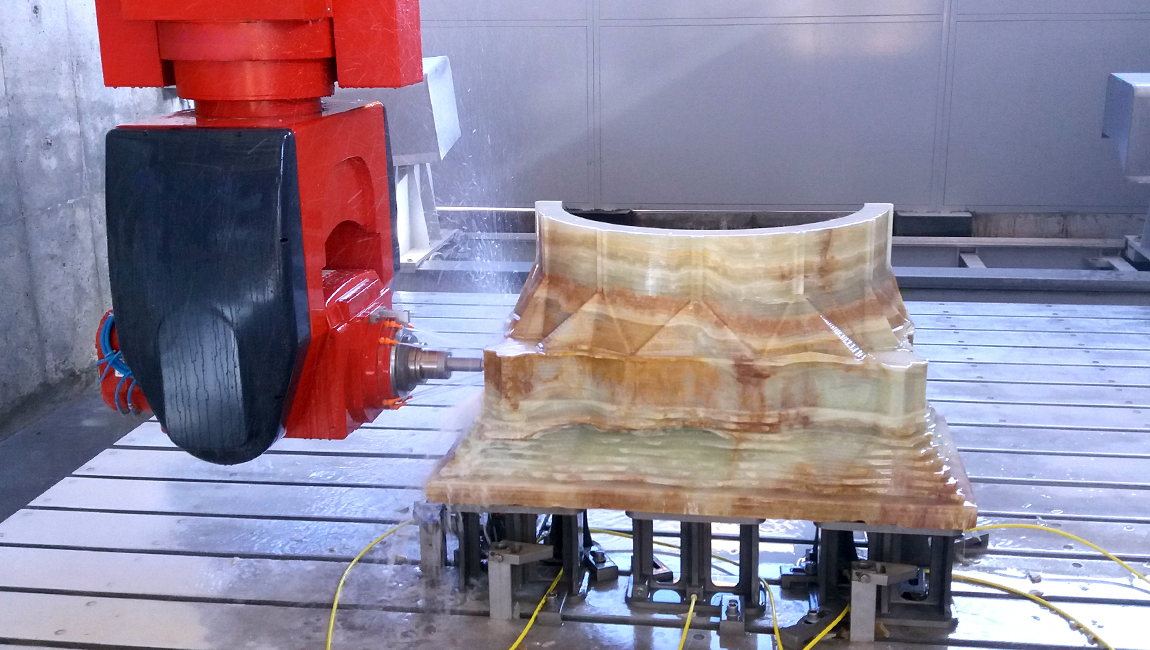

NC machining centre with 5 interpolating axes, for cutting and shaping workpieces

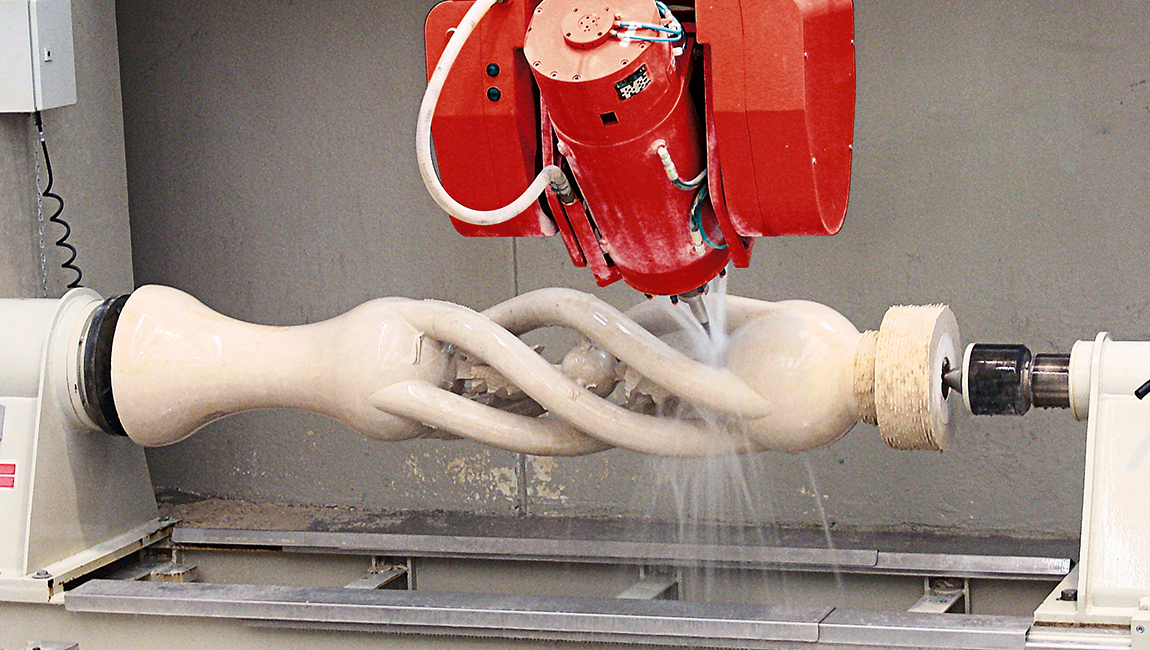

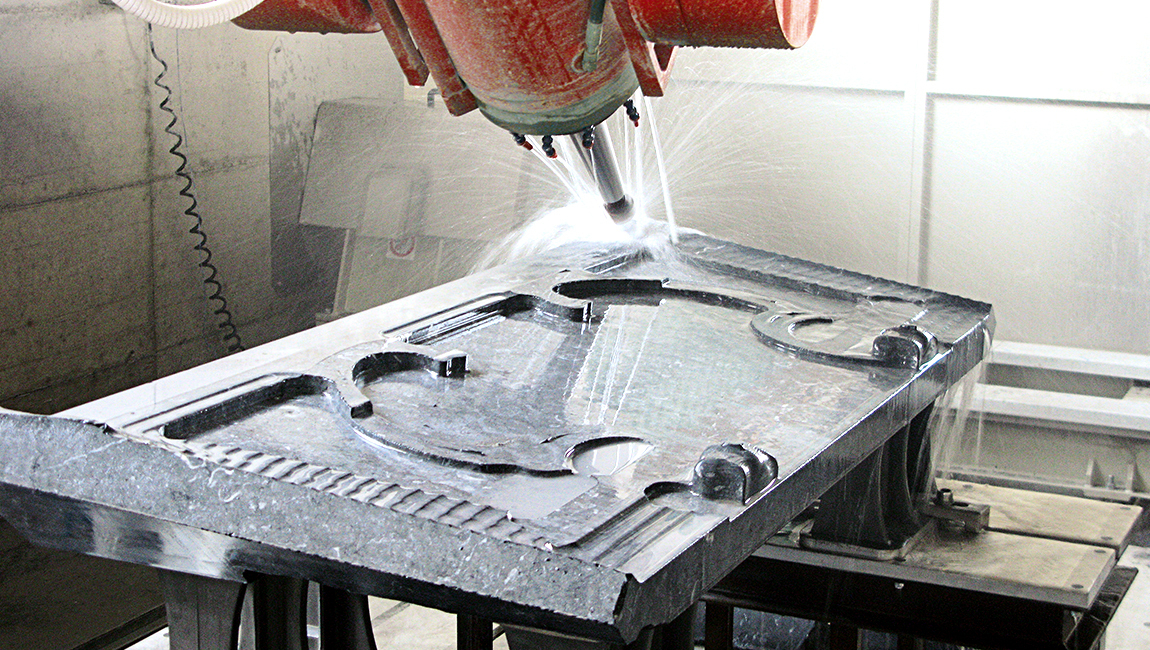

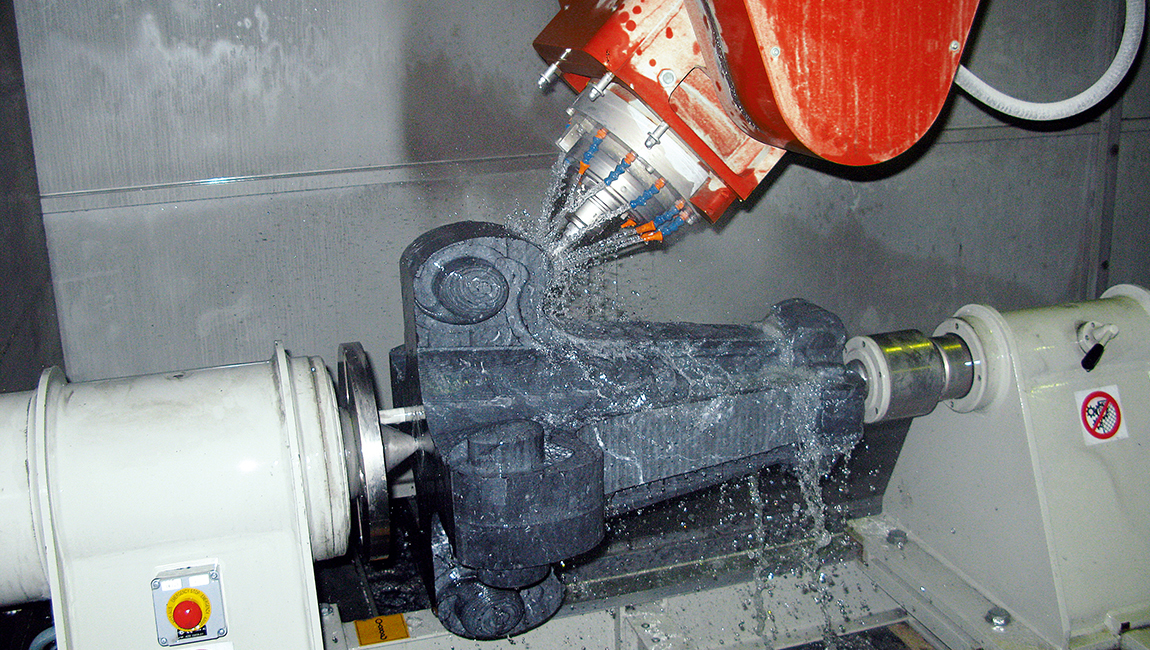

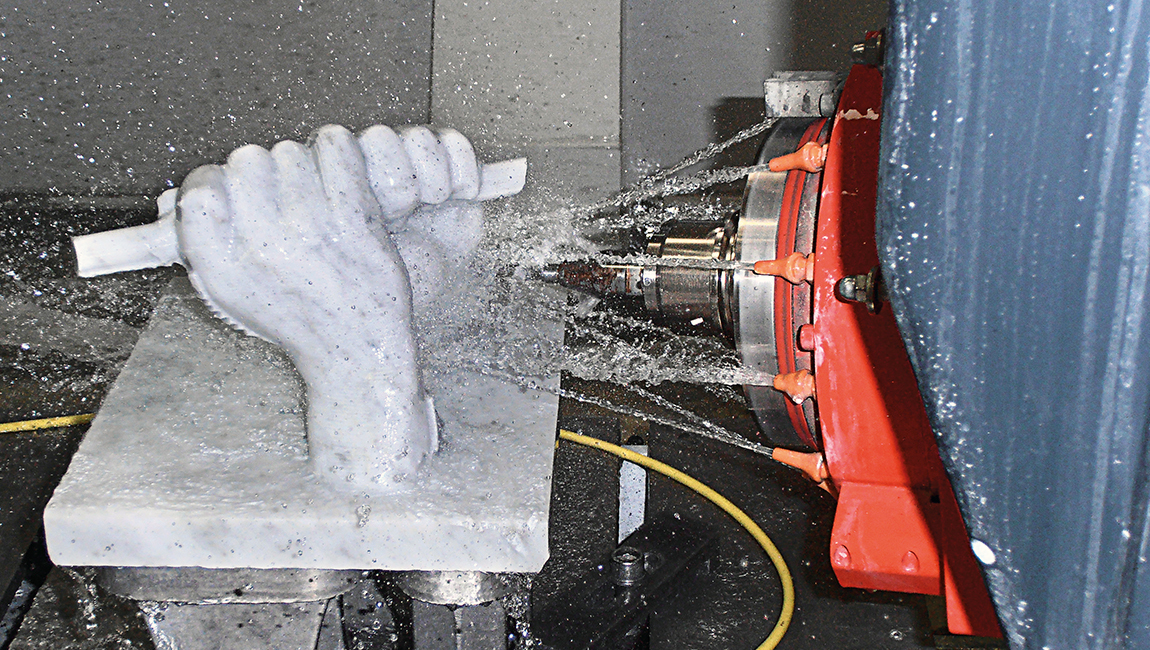

Shapemill is the machining centre designed for companies operating with very large workpieces and, especially, for machining of tough materials that require high power and torque. This machine is distinguished by its ability to combine milling and turning in a single set-up, exploiting the potential of the turning table and the automatic heads store to automatically switch from the powerful milling head to the boring bar head during the machining process.

It's a multifunction 5 axis machining centre for cutting, shaping, block slotting, turning and milling, making of statues and columns.

Breton Shapemill

Reasons why

Top level performance and configuration options

The Shapemill range is primarily available in 2 versions: 1600 and 2000.

With Z axis strokes up to 1,500 mm, cross strokes up to 4,000 mm and longitudinal strokes up to 30,000 mm, Shapemill is the machining centre for tough materials with the highest operating volume in the Breton range.

Thanks to the various compatible tool stores, automatic tool or cutting disc changes allow the machining centre to operate in unmanned mode.

Both versions can be equipped with a cutting disc up to 1000 mm in diameter.

The possibility of adding the tool store, in the “straight” and “circular” available versions, results in high capacity for machining with milling cutters and grinding wheels for shaping.

Each aspect of Shapemill is designed to produce top results. The structure has been optimised using FEM (Finite Element Method) and FMEA (Failure Mode and Effect analysis) techniques in order to achieve the best compromise of stiffness, versatility, and function. Shapemill also stands out for its reliability. All mechanical and electronic components are top quality, while assembly operations are carried out by Breton's expert technicians, all factors that guarantee long product life and reduced maintenance.

Materials

Processes

Industries

Finished products

Technologies

Numerical control

Spindle power

Patents

Spindle torque

Technological highlights

Other versions of Breton Shapemill

Version comparative table

| SHAPEMILL 1600 K28 | SHAPEMILL 1600 K55 | SHAPEMILL 2000 K28 | SHAPEMILL 2000 K55 | |

|---|---|---|---|---|

"Z" axis travel (with "A" axis at 0°) | 1600 mm | 1600 mm | 2000 mm | 2000 mm |

Spindle motor power (in S1 duty) | 30 kW | 30 kW | 30 kW | 30 kW |

Max. spindle rotation speed | 10000 rpm | 10000 rpm | 10000 rpm | 10000 rpm |

Tool holder | HSK-B100 | HSK-B100 | HSK-B100 | HSK-B100 |

"X" axis travel | 4000 mm | 4000 mm | 4000 mm | 4000 mm |

"Y" axis travel | 2800 mm | 5500 mm | 2800 mm | 5500 mm |

"X" axis max. displacement speed | 40000 mm/min | 40000 mm/min | 40000 mm/min | 40000 mm/min |

"Y" axis max. displacement speed | 40000 mm/min | 40000 mm/min | 40000 mm/min | 40000 mm/min |

"Z" axis max. displacement speed | 30000 mm/min | 20000 mm/min | 20000 mm/min | 20000 mm/min |

"A" axis rotation | 0 - 115 ° | 0 - 115 ° | 0 - 115 ° | 0 - 115 ° |

"C" axis rotation | 400 ° | 400 ° | 400 ° | 400 ° |