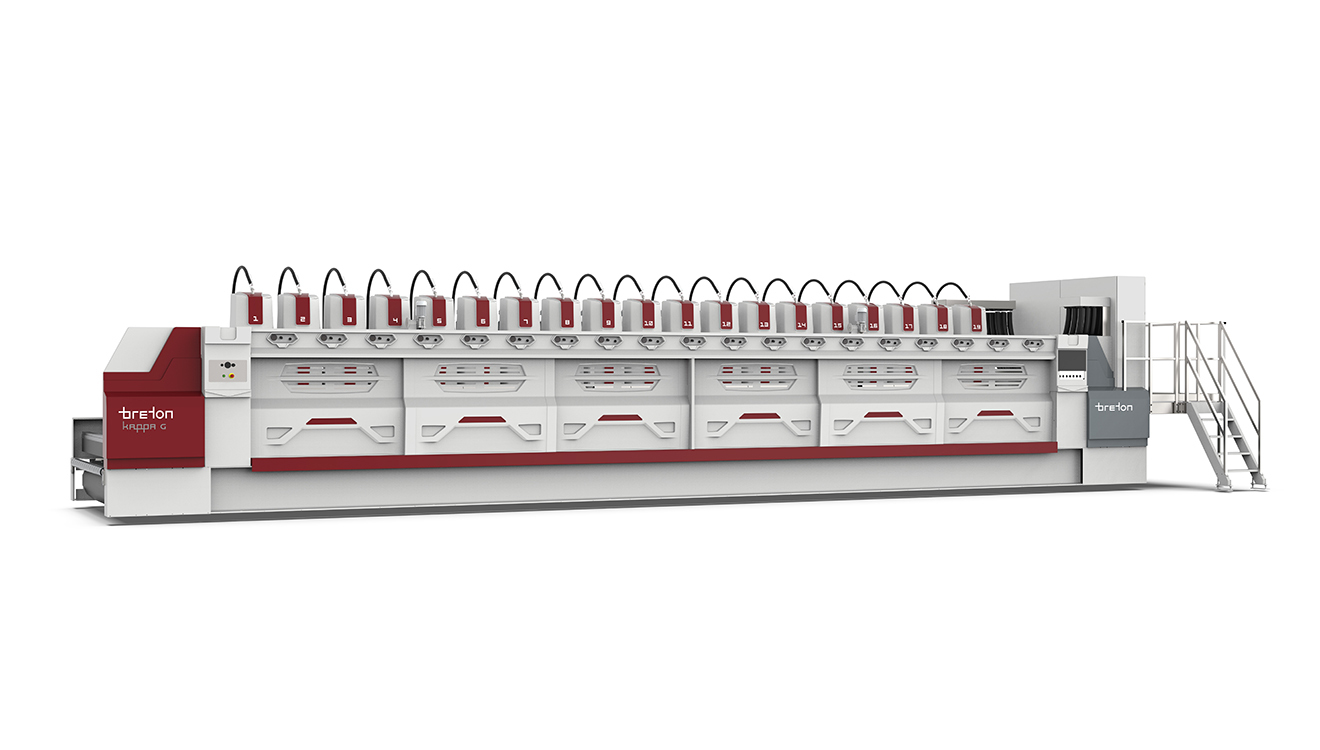

Among its key innovations, the machine features solutions engineered to improve efficiency, precision, and reliability, including a spheroidal cast iron spindle housing, a sturdy legless base, a gantry electronic axis beam drive, and more.

From a technological standpoint, a key feature is the exclusive Tetrix system, which enables the simultaneous processing of slabs of varying widths, without the need for unloading, while also allowing for continuous edge polishing. Enhancing the machine’s capabilities, the patented Tango system applies a controlled oscillating motion to the spindles, significantly boosting the uniformity and quality of the finish.

The Kappa G 6000 also stands out for its exceptional configurational versatility, with the option to equip it with 6-, 8-, or 10-abrasive brick heads, as well as Mirage heads, to accommodate a broad range of production requirements.

In addition to its new features, the machine retains several elements from the previous version—including the front-mounted spindle, dual lifting cylinder, a reinforced cross-section beam, and advanced electronics with digital drives and brushless motors—all designed to ensure maximum reliability and uninterrupted operation.