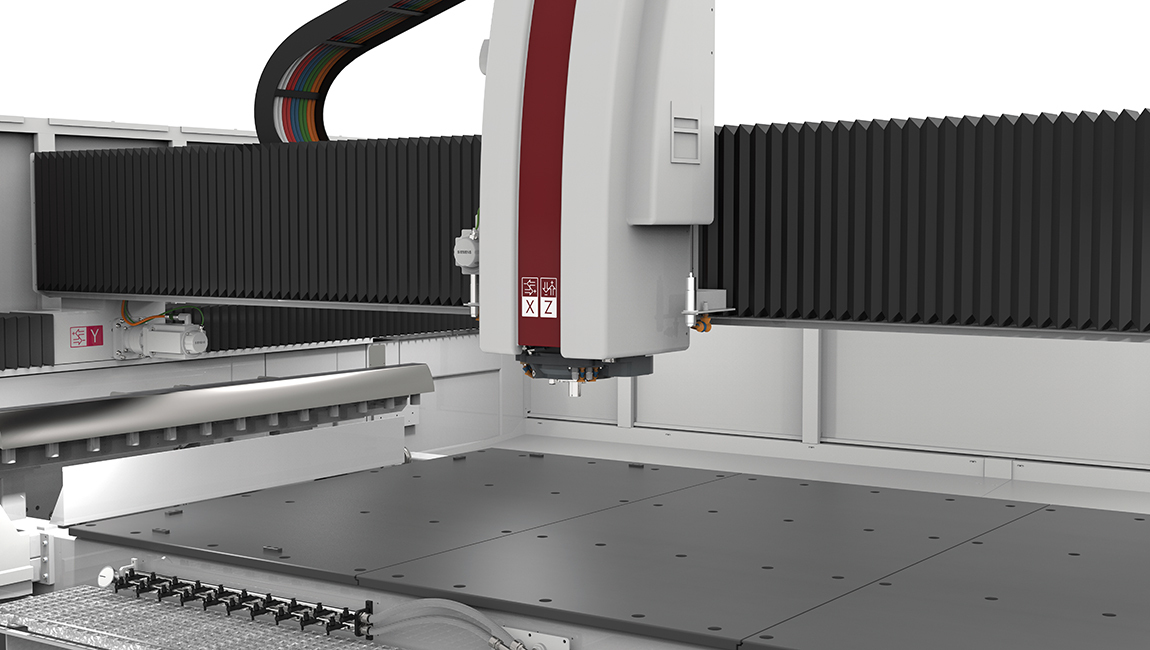

The spindle developed by Breton guarantees exceptional performance levels with its power of 16 kW and speed of 14,500 rpm, making it possible to maintain high working speeds even with very small diameter tools.

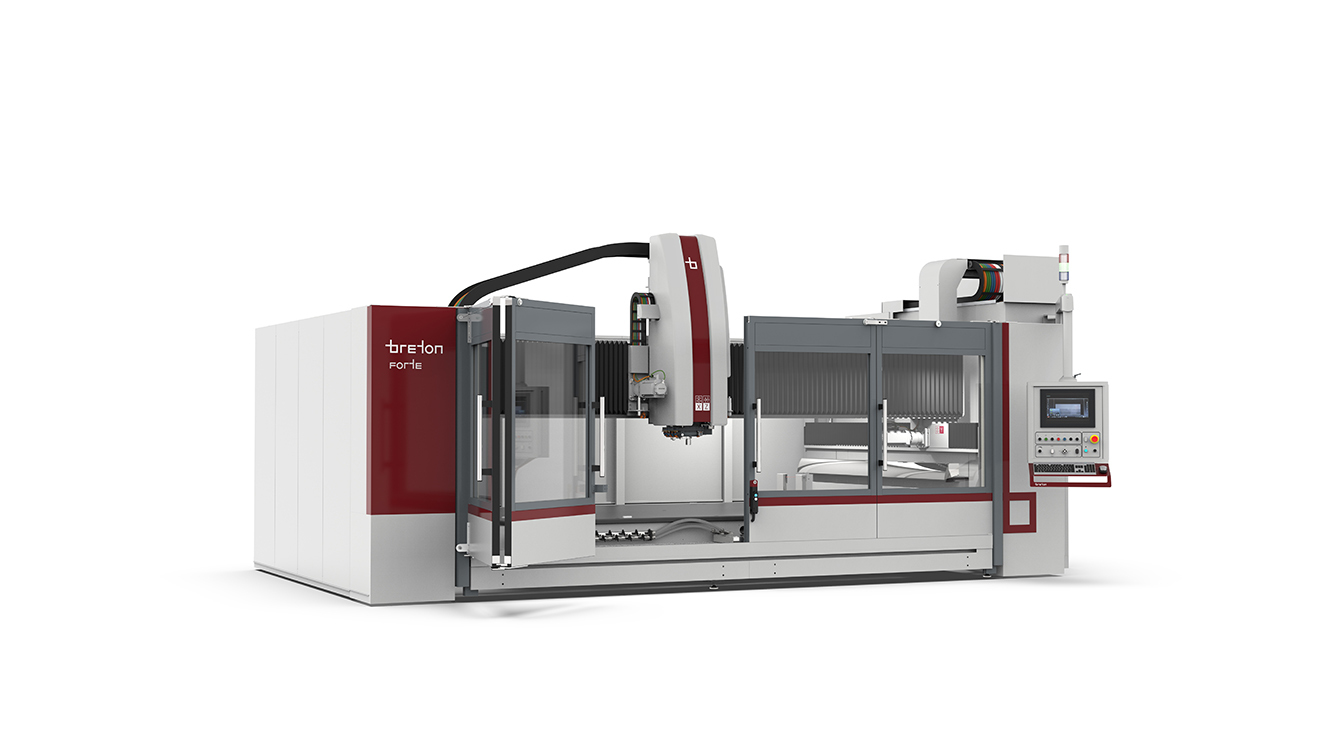

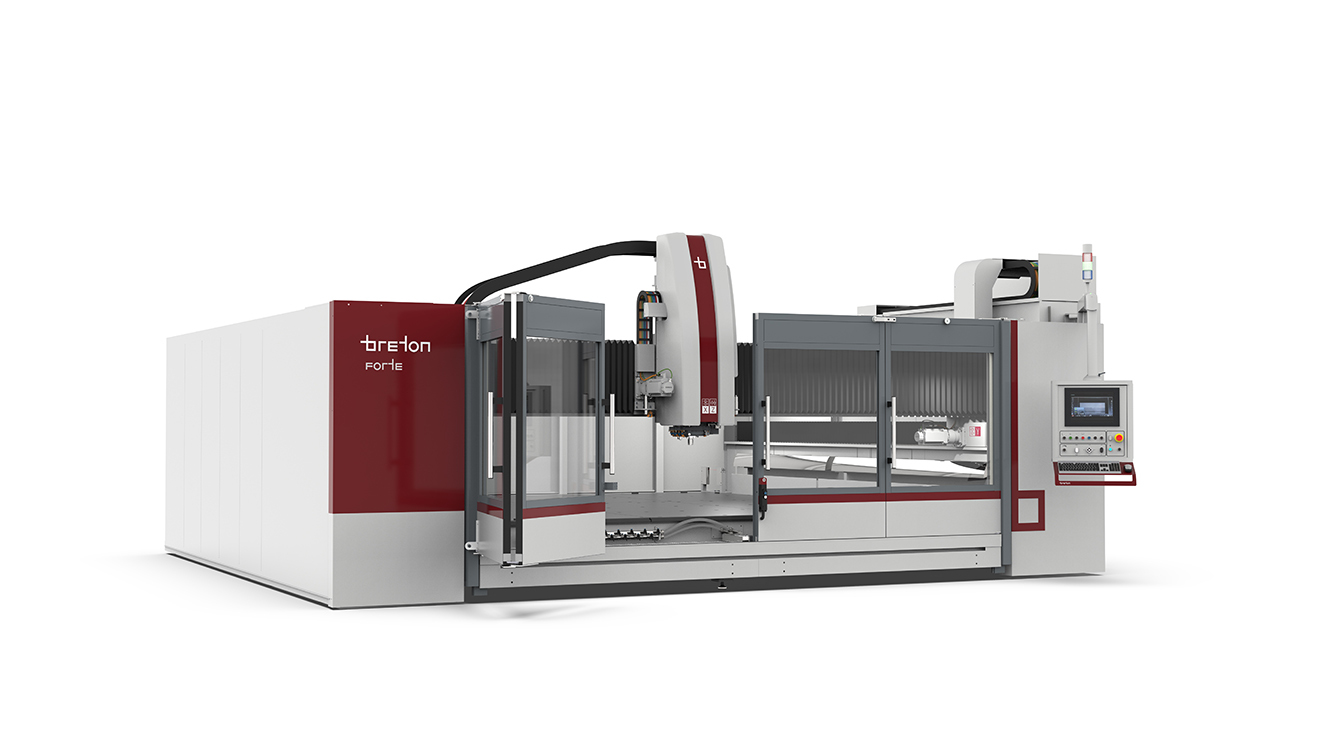

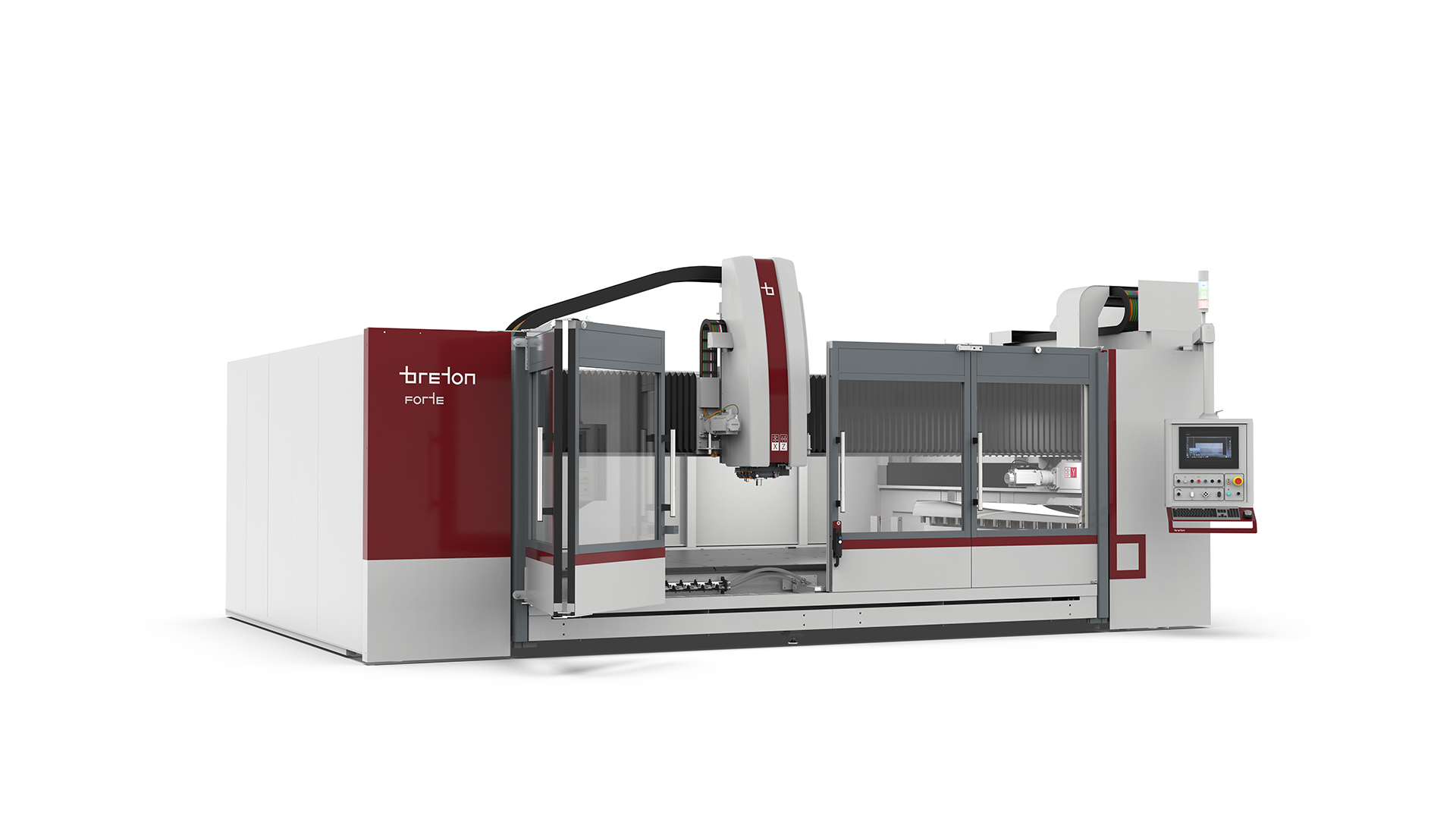

3 and 4 axis high output monobloc contouring centre

Its structural robustness and exceptional mechanical and electronic reliability mean the machine is ideal for drilling, shaping and contouring in applications such as kitchen worktops, vanity tops, and furnishing accessories.

Breton Forte

Reasons why

The robustness and repeatability that was lacking

All Breton Forte, Compact, Wide and Extreme models are characterised by muscular 16 kW 12,000 rpm spindle that offers all the power and torque needed to perform the required operations effortlessly, even with very small diameter tools.

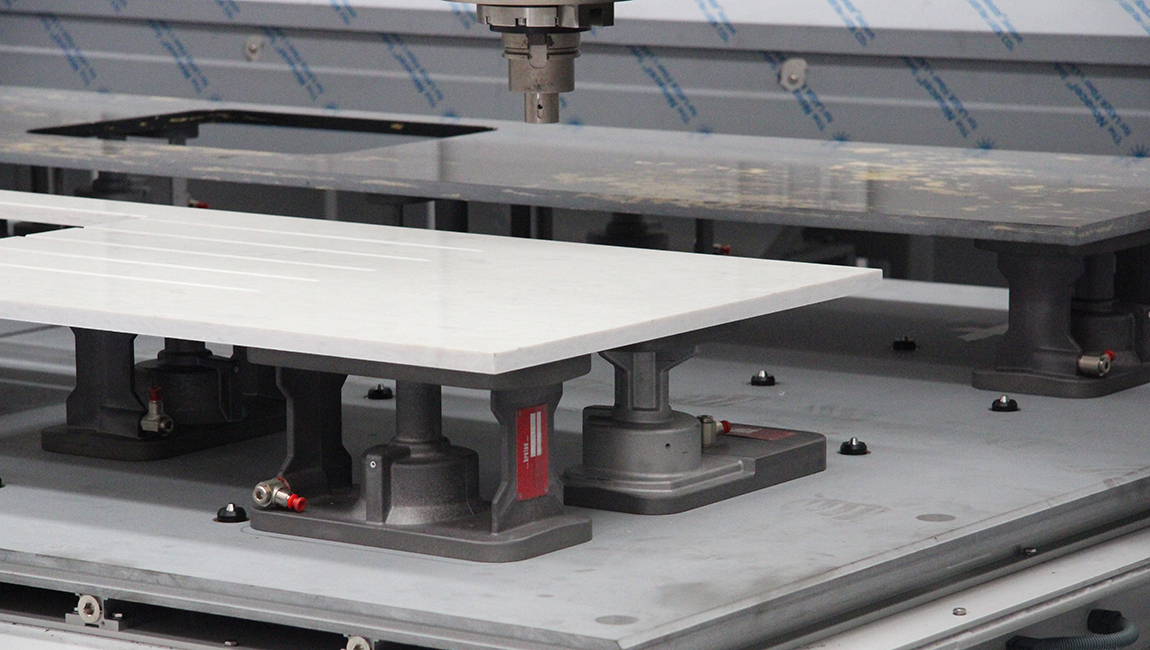

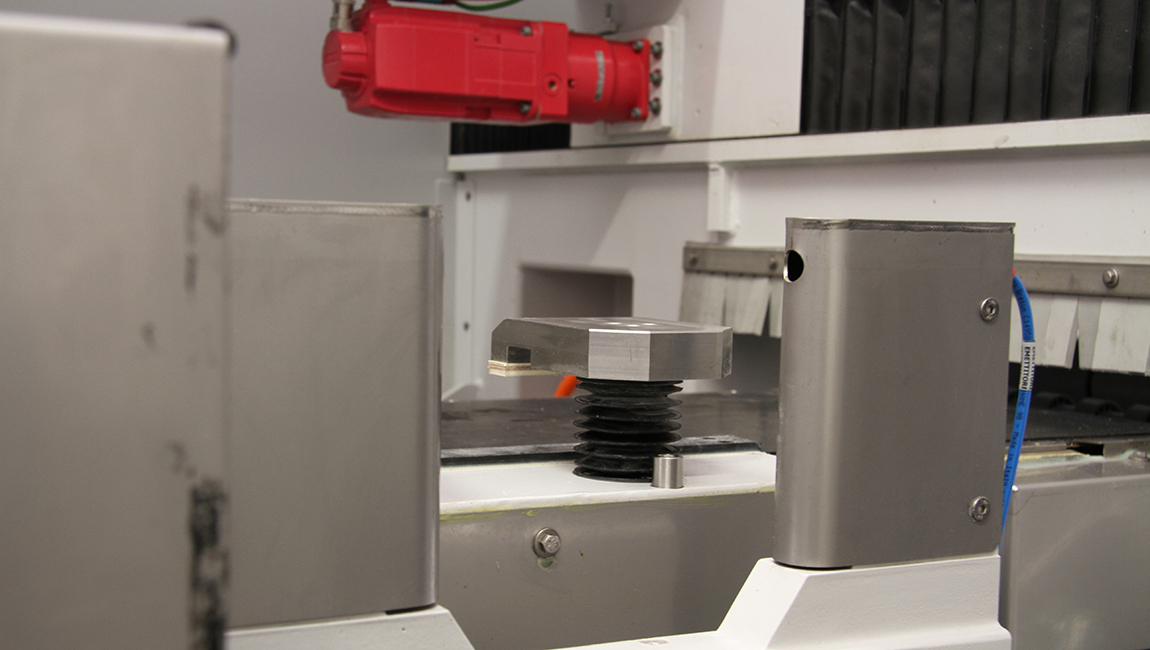

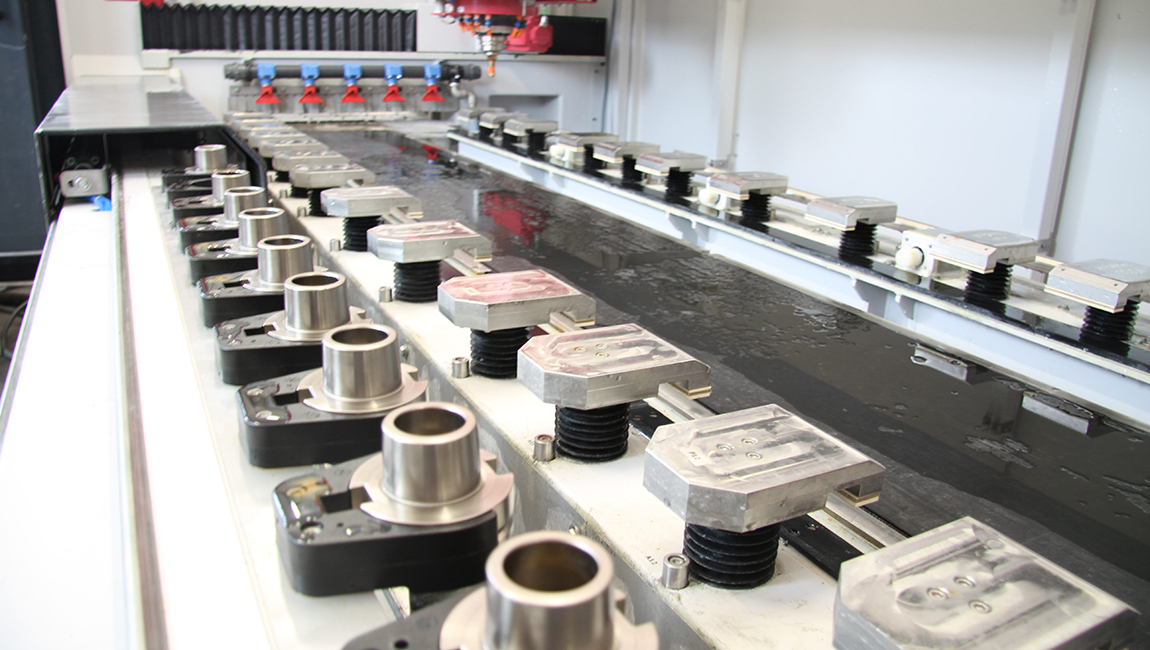

The work table size affects the number of workpieces that can be loaded simultaneously in order to optimise the number of tool changes and set-up times.One major benefit is gained by opting for the Metalquartz work table, which offers exceptional stability and is not subject to corrosion, unlike conventional steel work tables. Grinding is easy in the extreme, thanks to the composition of the table in a special quartz based composite so the process can be performed using the same tools used by the machine for normal production operations.

Forte is also available in high output versions, designed to increase the quantity of parts produced.

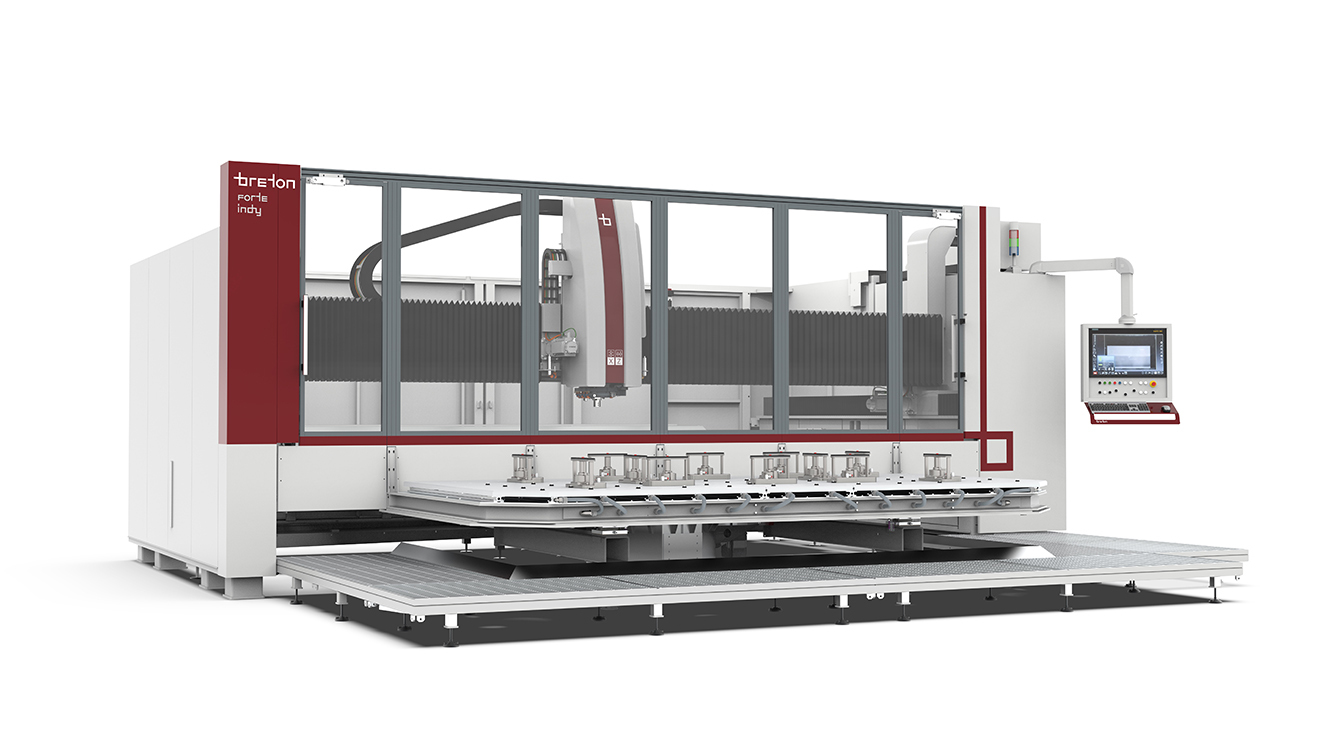

Forte Indy is equipped with a dual rotary work table that makes it possible to load/unload the workpieces while machining proceeds, thereby reducing idle times.

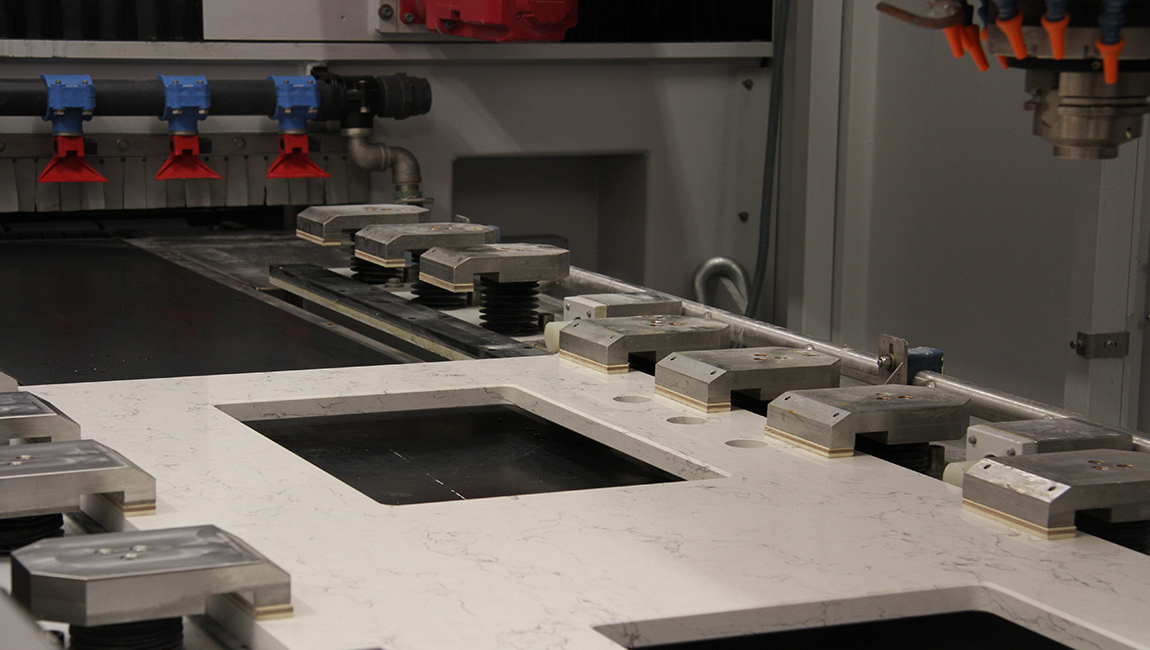

Forte Flux, on the other hand, is distinguished by its workpiece feeding and clamping system. In this system, the workpieces are moved on a conveyor belt and clamped for machining by means of pneumatic grippers instead of the classic vacuum pods. The machine operates fully independently; workpieces can be changed in less than a minute and sink cutout unloading, if necessary, is performed without interrupting the work cycle.

Forte Flash 3 and 4 axis high output contouring centre, driven by linear motors.

The extreme speed and acceleration of the axes, combined with a powerful high-speed spindle, reduces machining times and thus increases productivity.

Materials

Processes

Industries

Finished products

Technologies

Numerical control

Patents

Technological highlights

Other versions of Breton Forte

Version comparative table

| Forte Compact | Forte Wide | Forte Extreme | Forte Indy | Forte Flux | Forte Flash | |

|---|---|---|---|---|---|---|

Dimensions of the workbench (length) | 3740 mm | 3740 mm | 3740 mm | 3790 mm | 3450 mm | 3740 mm |

Dimensions of the workbench (width) | 1900 mm | 2240 mm | 3940 mm | 1860 mm | 400 mm | 2240 mm |

Max. tool length | 240 mm | 240 mm | 240 mm | 240 mm | 200 mm | 240 mm |

Max. tool diameter | 125 mm | 125 mm | 125 mm | 120 mm | 120 mm | 140 mm |

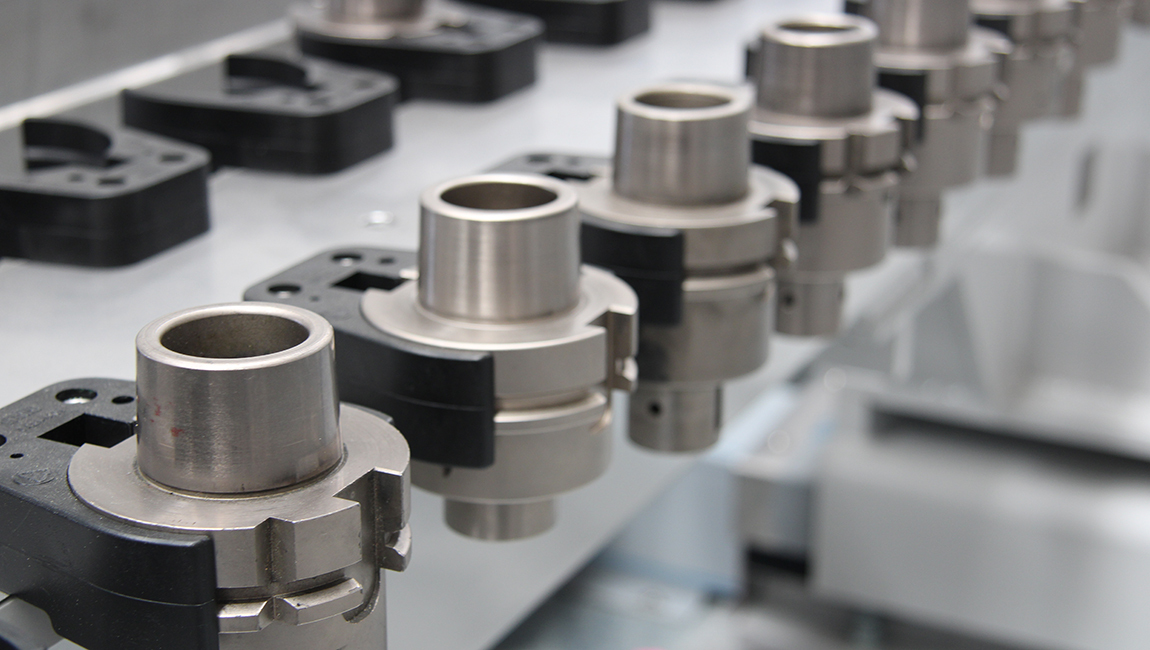

Tool holder | HSK-B80 | HSK-B80 | HSK-B80 | HSK-B80 | HSK-B80 | HSK B80 |

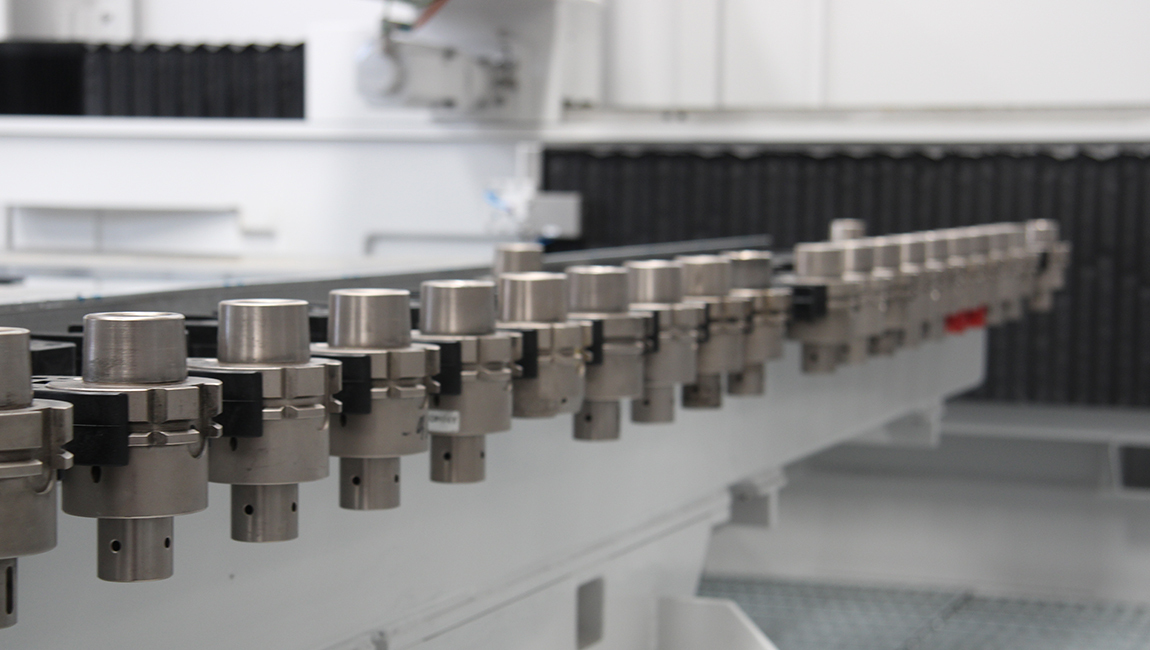

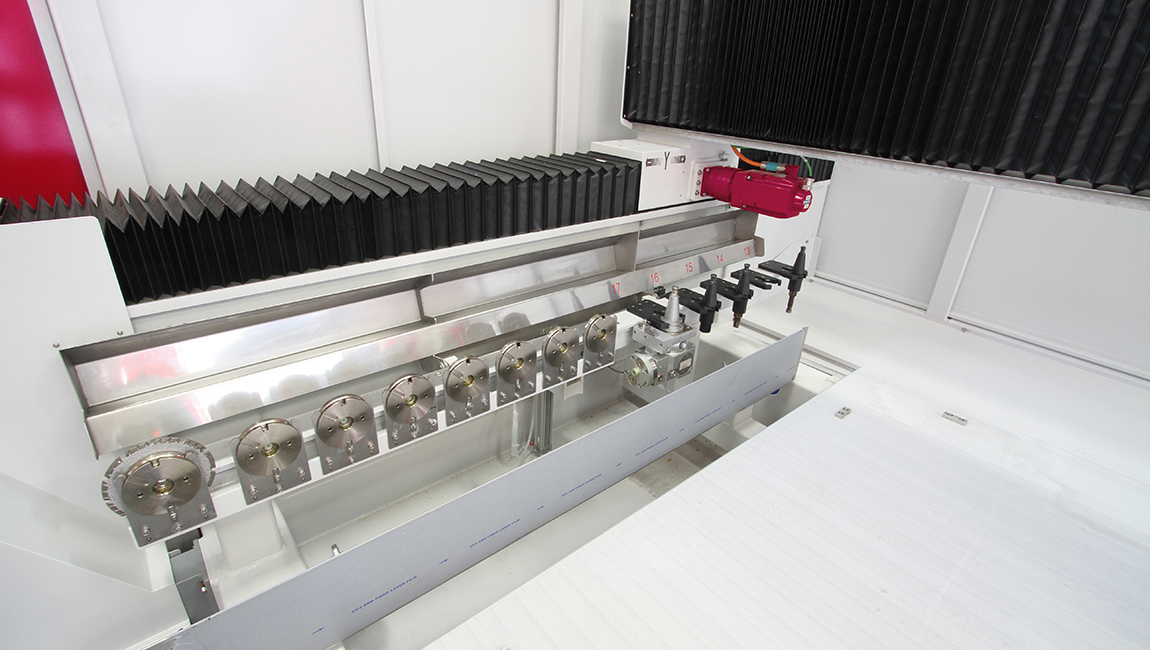

Tool store capacity | 15+15 | 17+17 | 31+31 | 53 | 20 | 32 |

"X" axis travel | 3800 mm | 3800 mm | 3800 mm | 3800 mm | 3800 mm | 4400 mm |

"X" axis max. displacement speed | 80000 mm/min | 80000 mm/min | 80000 mm/min | 80000 mm/min | 80000 mm/min | 150000 mm/min |

"Y" axis travel | 1950 mm | 2300 mm | 4000 mm | 1800 mm | 1110 mm | 2300 mm |

"Y" axis max. displacement speed | 60000 mm/min | 60000 mm/min | 60000 mm/min | 60000 mm/min | 60000 mm/min | 100000 mm/min |

"Z" axis travel | 300 mm | 300 mm | 300 mm | 300 mm | 300 mm | 320 mm |

"Z" axis max. displacement speed | 30000 mm/min | 30000 mm/min | 30000 mm/min | 30000 mm/min | 30000 mm/min | 30000 mm/min |

Spindle motor power (in S1 duty) | 16 kW | 16 kW | 16 kW | 16 kW | 16 kW | 16 kW |

Max. spindle rotation speed | 14500 rpm | 14500 rpm | 14500 rpm | 14500 rpm | 14500 rpm | 16000 rpm |

Mass | 7500 kg | 8000 kg | 10000 kg | 12000 kg | 7000 kg | 8000 kg |

Overall dimensions (length) | 6900 mm | 6700 mm | 6700 mm | 6500 mm | 7900 mm | 7000 mm |

Overall dimensions (width) | 3320 mm | 3950 mm | 5500 mm | 6400 mm | 3450 mm | 4400 mm |

Overall dimensions (height) | 2700 mm | 2700 mm | 2700 mm | 2730 mm | 2950 mm | 2550 mm |