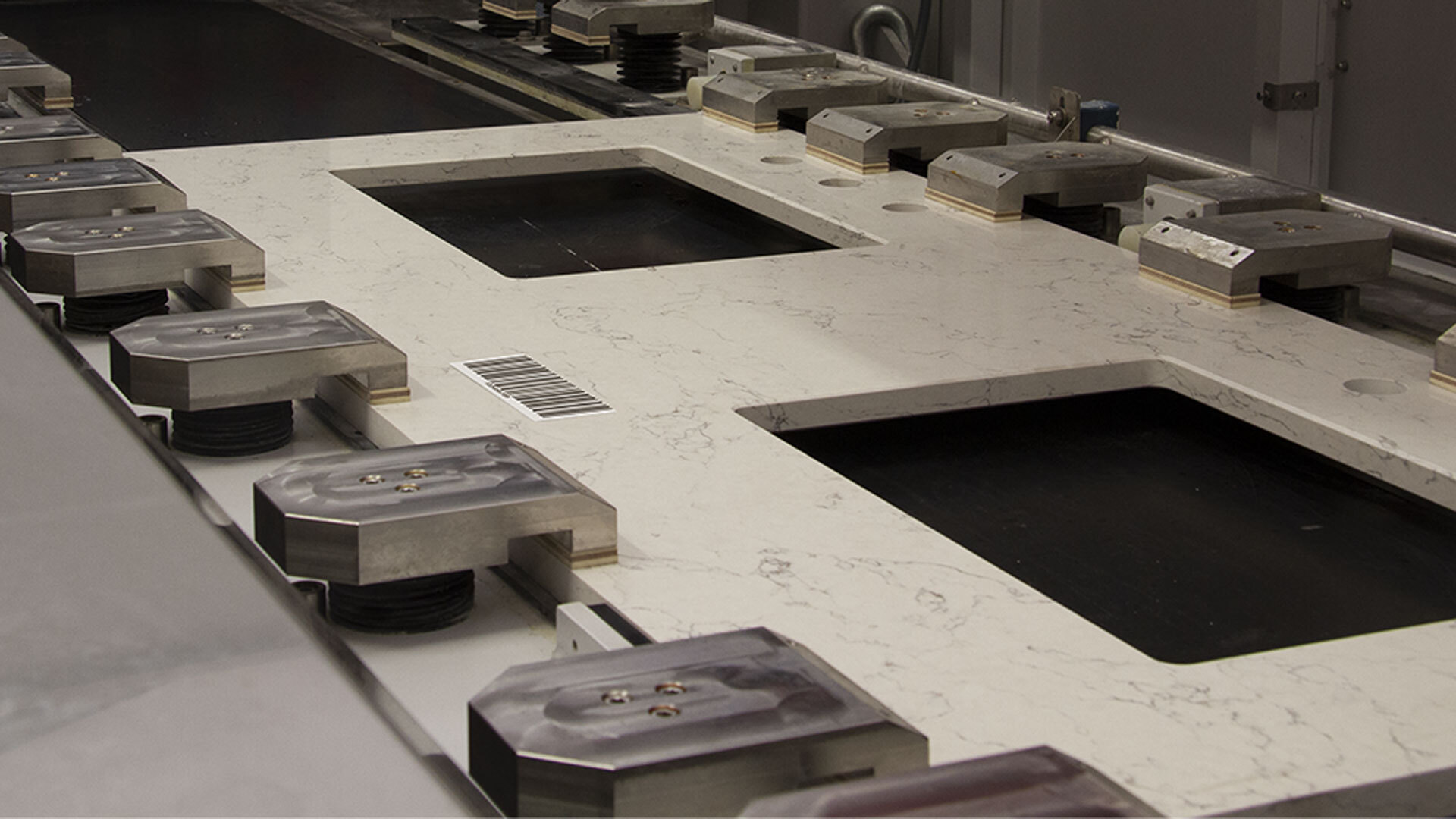

Among the various advanced functions, Breton Sphera is able to detect and decode any bar codes affixed to the slabs following photographic acquisition. In this way, Breton Touch identifies the slab and automatically matches the relative machining program previously prepared in the office or, if desired, even on board the machine.

Article

Why and how to track slab manufacturing process

The benefits of tracking the process of transforming slabs into semi-finished or finished products

A complex process to keep under control

Producing finished stone products from slabs is a complex process involving different phases.

There are many factors and information that need to be kept under control, and it is not always easy to do so: in the absence of a tracking system, it all depends on the experience of the people involved.

The following topics will be covered:

- the benefits of tracking the process of transforming slabs into semi-finished or finished products;

- the phases involved;

- barcodes;

- available technologies.

The benefits of tracking the process

Implementing the tracking of the production process brings considerable benefits. Basically, it speeds up the spread of information.

This implies the following:

- an increase in the speed of activities execution;

- an increase in information sharing;

- the definition of the information to be considered important for the different and individual processing steps, while maintaining the possibility of retrieving all the others;

- controlling the entire process to maximise efficiency.

Which phases it involves

Tracking involves the entire production process and can be applied to any production phase, depending on the degree of automation to be achieved.

-

/01

It can start from the acquisition of customer orders, then move on to the selection of the blocks to be cut or, in the case of those who already buy the semi-finished product, of the most suitable slabs in stock and the subsequent processing to be carried out.

-

/02

Tracking is also important in the quality certification of the finished product, allowing evidence of its origin, processing or treatments applied.

-

/03

Furthermore, it can be used in the installation of the product in order to respect the original design, the management of the grain or the quick replacement of any pieces damaged in the operations.

Barcodes

The basis of tracking any manufacturing process is an encoding of information. The most widely used version of coding is barcodes.

A barcode, defined as 'a form of machine-readable information on a scannable visual surface' is a set of lines of different widths and heights and a sequence of letters and numbers. Using a barcode scanner, the sequence is scanned and then processed and returned in a computerised version.

Historically, barcodes were born on 7 October 1948 from an idea of Norman Joseph Woodland and Bernard Silver, two engineering students at Drexel University, after hearing the need to automate checkout operations from the president of a food company.

After numerous developments and attempts, Woodland developed linear barcodes at IBM, which were adopted on 3rd April 1973 under the name 'UPC' (Universal Product Code).

On 26th June 1974, the first product (a packet of American tyres) was sold using a barcode reader at a supermarket in Troy, Ohio. That packet of gum is now in the Smithsonian's National Museum of American History.

Barcodes are therefore a tool that summarises a variety of information such as the origin of a product, its characteristics, the processing it has undergone and its destinations.

Available technologies

Breton provides a complete set of t to achieve effective and complete tracking to turn any laboratory, large or small, into a Smart Factory.

In order to enable the tracking of your slab treatment and finishing production process, you need to be equipped with a series of technological tools, such as:

- software platforms for managing barcodes during the production process;

- technological devices for printing, applying and detecting barcodes.

Platforms and tools for a Smart Factory

Discover more?

Fill in the form below to get information about Breton products

Once you submit the form, please check your mailbox: we will send you a confirmation email. Please click the link to validate your request.