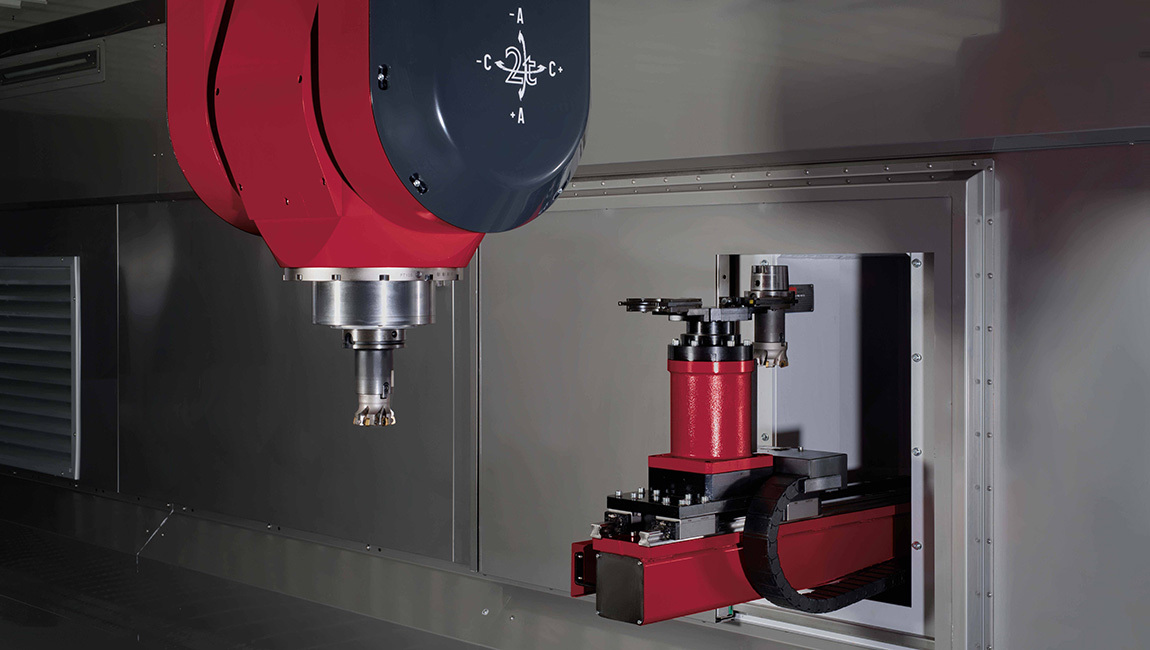

The use of Dual Drive motors guarantees high force for the most demanding operations exploiting the full power of both motors operating in the same direction. For higher precision work the preload value is increased automatically to obtain the maximum accuracy. In terms of energy usage, the Dual Drive system has lower current consumption than linear motors and it does not require dedicated cooling systems.

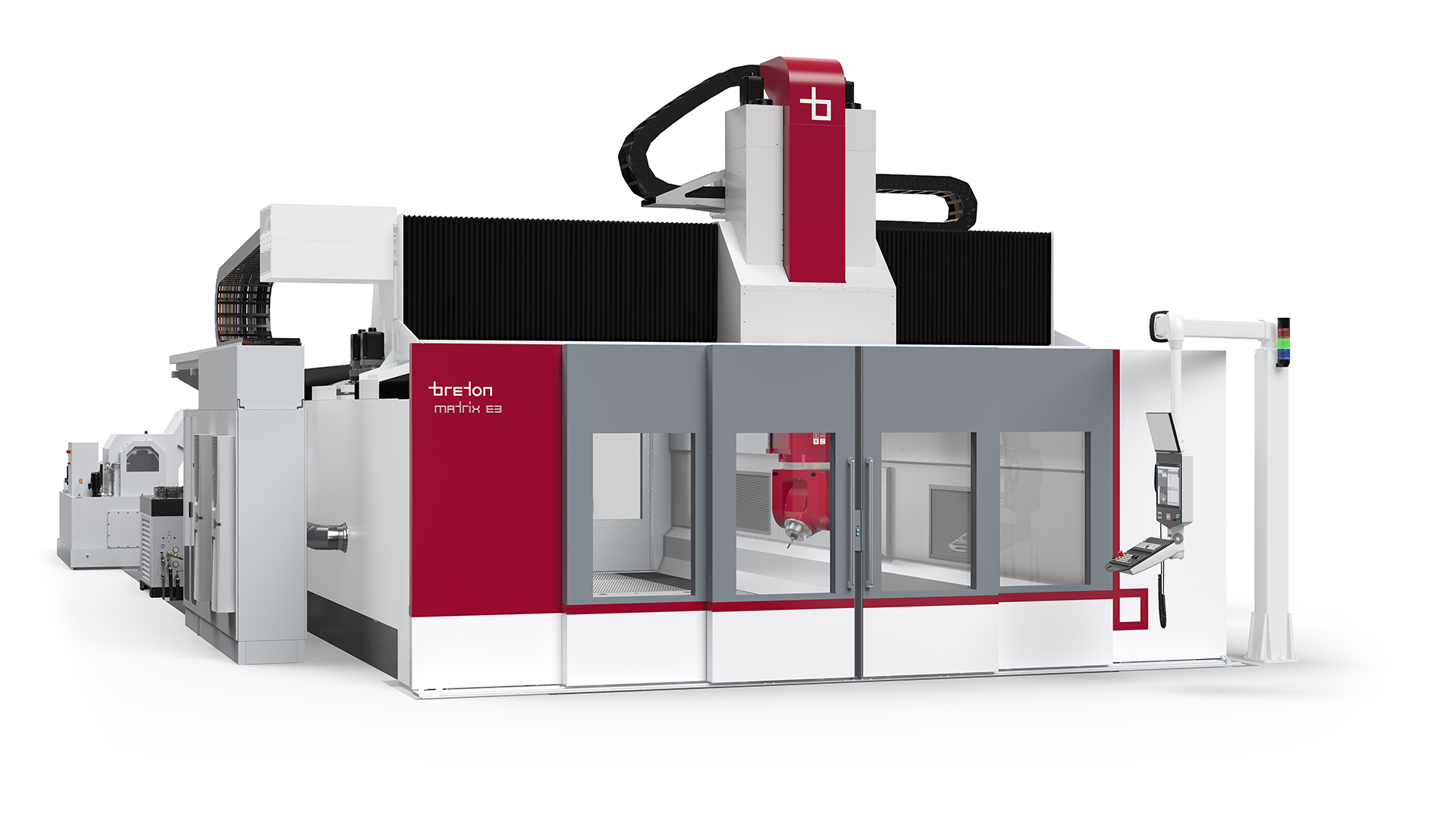

High dynamic and high precision modular 5 axis vertical gantry machining centre

The development of this machining centre was based on careful technical choices that combine thrust and robustness with dynamics and precision for perfect performance in hi-feed roughing, semi-finishing and finishing of large workpieces in steel, lightweight alloys, and special composites.

Breton Matrix E3

Reasons why

Far more than a machining centre

Matrix is a machining centre that combines the robustness and thrust required for roughing operations with the dynamics and precision needed for finishing. A stable and robust base that is also extremely dynamic, configurable with a broad range of components and accessories in order to handle entire machining processes in a large number of sectors.

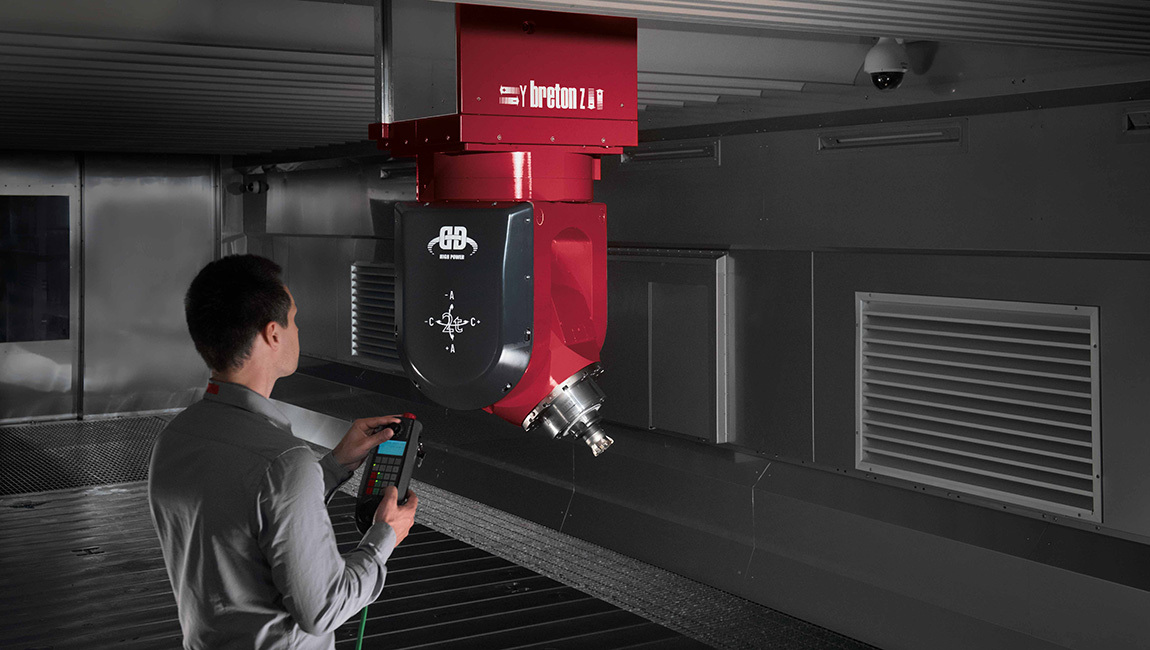

The Dual Drive motors guarantee power and precision; they move in unison to provide the maximum thrust when the machining process calls for sheer force, while they operate in preload mode to perform high-precision work. To guarantee superior surface finishes, Matrix E3 uses Breton’s High Dynamics and Thermal Shield technologies. The true benefit is to have all operations in a single set-up: roughing, semi-finishing, finishing, measurement, inspection and quality control of surfaces.