- Homepage

- Customer Stories

- A coffee with...Antonio Izzo (Seieffe Industrie, Italy)

Customer story

A coffee with...Antonio Izzo (Seieffe Industrie, Italy)

Discover what Antonio Izzo – Seieffe Industrie's Chief Executive, told us about his experience in the company, his marketing-oriented vision and the sales strategy implemented.

About Seieffe Industrie

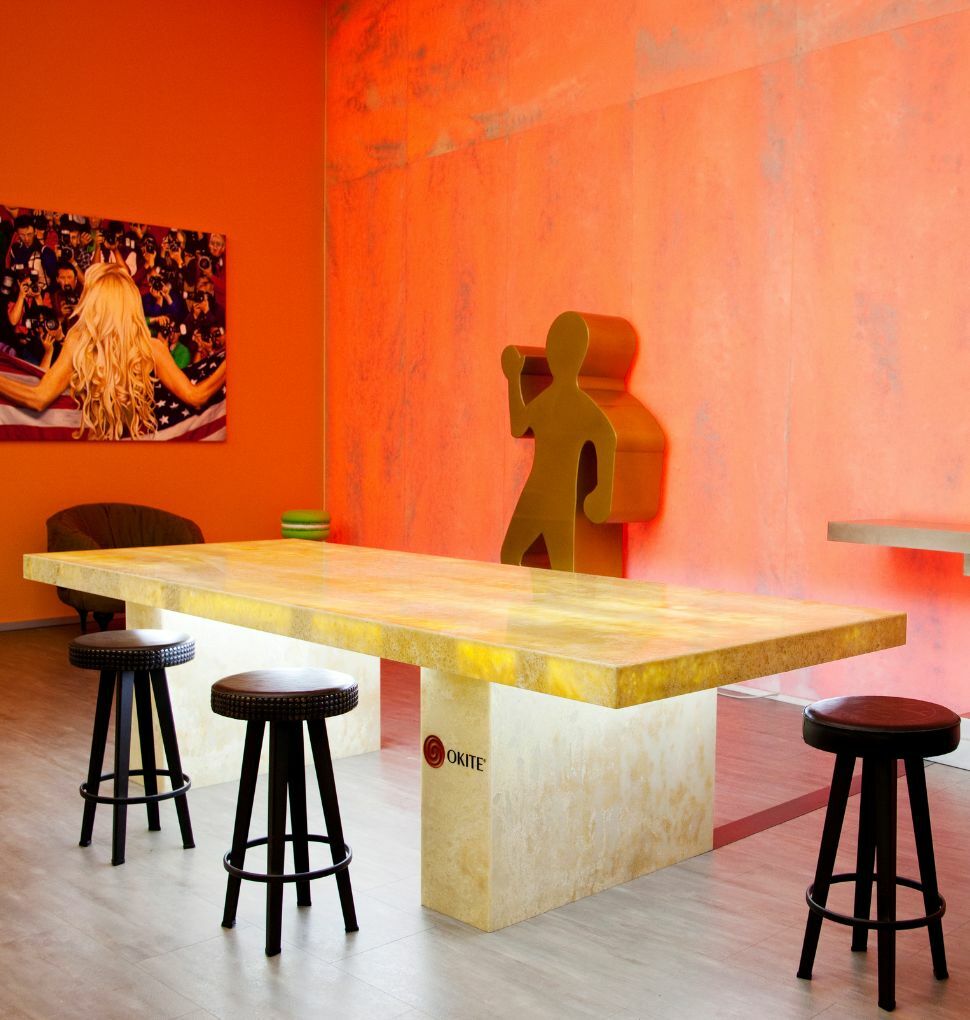

Seieffe Industrie, is a Company operating in the production of quartz-resin agglomerates using Bretonstone® technology; its material is known under the OKITE brand name. The company is located in one of the most beautiful historical and scenic places in Campania, the Caudina Valley, between two natural parks and the scene of the famous battle between the Romans and the Samnites "Le Forche Caudine".

It is one of the Izzo family companies and has an industrial tradition of over 60 years, which began with the founder Luigi Izzo, whose entrepreneurial history is characterised by winning choices pursued with enthusiasm and determination.

A commitment to innovation, care for design and constant research in the field of raw materials have led the company to expand its core business over the years. Founded as a company dedicated to the production of cement products and prefabricated elements - both in the public and private sectors- in the early 2000s it decided to diversify its production and enter the world of quartz surfaces.

Today, Seieffe is a solid industrial group headed by Antonio Izzo, which operates in various sectors: building construction, prefabrication and production of quartz surfaces for quality furniture. All the companies in the group are managed by the Izzo family.

From construction to quartz

Antonio Izzo's entrepreneurial path is marked by thoughtful and successful strategic choices. He entered the cement business when he was very young, and has led the company towards constant growth, leading it to excel in all sectors.

About his work experience, he says, "the crisis in both the public and private building sectors in the early 1990s led us to imagine an alternative business that would allow us to produce in Italy and export abroad, with the global market as a reference. Initially, we approached the world of ceramics, specifically porcelain stoneware, but being far from one of the most competitive industrial districts in the world, we soon abandoned this idea.

It was at this time that we approached Breton and the world of composite stone. We set up a new company under the name SEIEFFE (Sei Fratelli – Six Brothers) with Antonio Izzo as director. We created two production lines:

1. Bretonstone slabs

2. Terastone bricks

Even though we initially believed that Terastone could complement the ceramic product market, we quickly realised that we would have to focus on the production of quartz resin slabs.

The importance of marketing and communication

Dr. Izzo recalls the years before the plant start-up as crucial for the study of the target market and the definition of the marketing strategy, adding: "While the plants were being installed at our production site, we decided to study the engineered stone market in detail. We invested heavily in marketing and communication, promoting the product and taking part to the most important trade fairs in the sector. It was in 98-99 that we witnessed one of the biggest transformations in the quartz/resin agglomerate slab industry: its use as part of residential furniture, mainly kitchen and bathroom tops, replacing natural stone.

In addition to the Italian market, the two markets we initially focused on were USA and Middle East; we were immediately very satisfied, both in terms of production capacity and turnover.

The more the market grew, the more the big giants approached, Dupont, Samsung and LG to name but a few, and gradually quartz e-stone began to take the place of natural products, becoming the preferred product for kitchen and bathroom countertops.

How to bring a marble shop on board?

The success of the quartz e-stone product was undisputed at the beginning of 2000, but despite this, Mr. Izzo recalls, "marble workers were reluctant to work with it, continuing to prefer natural stone. Like us, all the other slab manufacturers had to deal with this problem. Some opted to open proprietary fabshops while we took a counter-current decision as far as the Italian market was concerned: we put our material on display directly in furniture showrooms.

The aim was to instil in end consumers the desire to put quartz e-stone countertops in their homes and trigger a chain reaction on the fabrication workshops. It was a winning choice. The marble workers soon realised that they could use the same machines as for natural stone and achieve a higher margin without having to search for customers - since the promotion, marketing and advertising was done by us.

It didn't take long to build up a network of trustworthy fabricators to whom customers interested in the product could be directed.

OKITE, the kitchen countertop

In Italy, Seieffe invested heavily in its brand and, even today, for many consumers Okite is the first request and the most recognised brand.

A simple and direct message was coined - Okite, the kitchen countertop - which, combined with a widespread communication strategy on television, in national and sector newspapers and a dense sales network throughout Italy, has led the company to be recognised as a reference point in the sector.

Mr. Izzo added "even today, after 20 years, the Okite name still appeals. The brand is strong and the quartz on the Italian market continues to be Okite. I am very satisfied with this. In the past, it happened several times that they falsified the certification of our product, we had to claim respect for our rights, urging them to transform the classic paper certification into a digital card that could be issued exclusively by us. We have always considered it essential to emphasise the quality of our product compared to other quartz products on the market - even to be able to justify a higher cost. In this respect, we have turned down orders when we were asked to remove the Okite brand from the slabs.

The Okite brand is a guarantee of quality, of the company reliability and should therefore always be evident on our products.

A new beginning with a historical partner: Breton

After a political break which kept Mr. Izzo busy in the area for about ten years, preventing him from following the movements of the quartz market in detail, Seieffe has now fully re-entered the sector.

Of that period, Mr. Izzo remembers "We lost a few years, due to my political activity, but now with the help of my sons Luigi and Marcello and a renewed and motivated team of collaborators we have reinforced the plants, in total three Okite production lines, expanding the commercial proposal with an attractive range of products.

We have developed our own technology to produce the veined products; together with the R&D department, we have studied the best way to manipulate the material and we have our own know-how to create specific equipment for the result.

I am particularly proud of the level of technology we have mastered, we have combined our idea of technology with that of Breton and achieved a very good result. We worked on a pilot plant and today we are at full production capacity.

The relationship with Breton has been essential for our growth. It's an excellent company managed with a lot of dedication and passion by the Toncelli family, it's a company that has always been there for us, even in difficult times.”

The future of quartz market

"Today, we are in a phase of generational change at Seieffe. Young people have been joining us and they are bringing a breath of fresh air, enthusiasm, energy and experience.

We are living in a particular moment: the market is shrinking because of Covid and we imagine that the 'new normal' will force us to find alternative ways of approaching the market. We must continue to improve and perfect the product, giving more service to the customer and to those who prefer us.

Currently, there are two main challenges we are facing: keeping up with technological evolution and ensuring high levels of security within the company. As far as technology is concerned, a great effort has been made over the last few decades and it is now possible to produce slabs of giant dimensions, extra-thin thicknesses and with aesthetic effects that were unimaginable just a few years ago. This allows us to significantly expand the applications of our products, increasing their popularity.

As far as safety is concerned, we are aware that crystalline silica is a serious problem. Also coming from the mining business, we have always been particularly sensitive to this issue, and it has helped us at SEIEFFE to refine our control measures in order to reduce the risk to below the levels set by law.

The Bioquartz® industrialised by Breton is a valid solution, but a major information campaign is needed so that the stonemason understands the higher levels of safety for himself and his workers.

Related articles

- Customer storyA coffee with...Santiago Alfonso (Cosentino, Spain)

Discover what Santiago Alfonso – Director of Strategic Communication & Corporate Reputation at Cosentino, told us about how Cosentino became a customer-centric company, a reliable partner and the undiscussed leader in the E-Stone Industry.

- Customer storyA coffee with...Vittorio Baghin (Agglo Baghin, Italy)

Discover what Vittorio Baghin - CEO of Agglo Baghin - told us about his entrepreneurial experience in the Engineered Stone Industry, the unique relationship with his international customers and the attention to the technical-aesthetic characteristics of the finished product.

- ArticleStory of BretonStone

The story of a dream come true. The story of a man: Mr. Marcello Toncelli.