The use of a Dual Drive system with two motors guarantees high force for the heaviest duty operations, exploiting the power of both motors delivering their maximum output in the same direction. For higher precision work the preload value is increased automatically to obtain the maximum accuracy.

The Dual Drive system has lower energy consumption than linear motors and it does not require dedicated cooling systems.

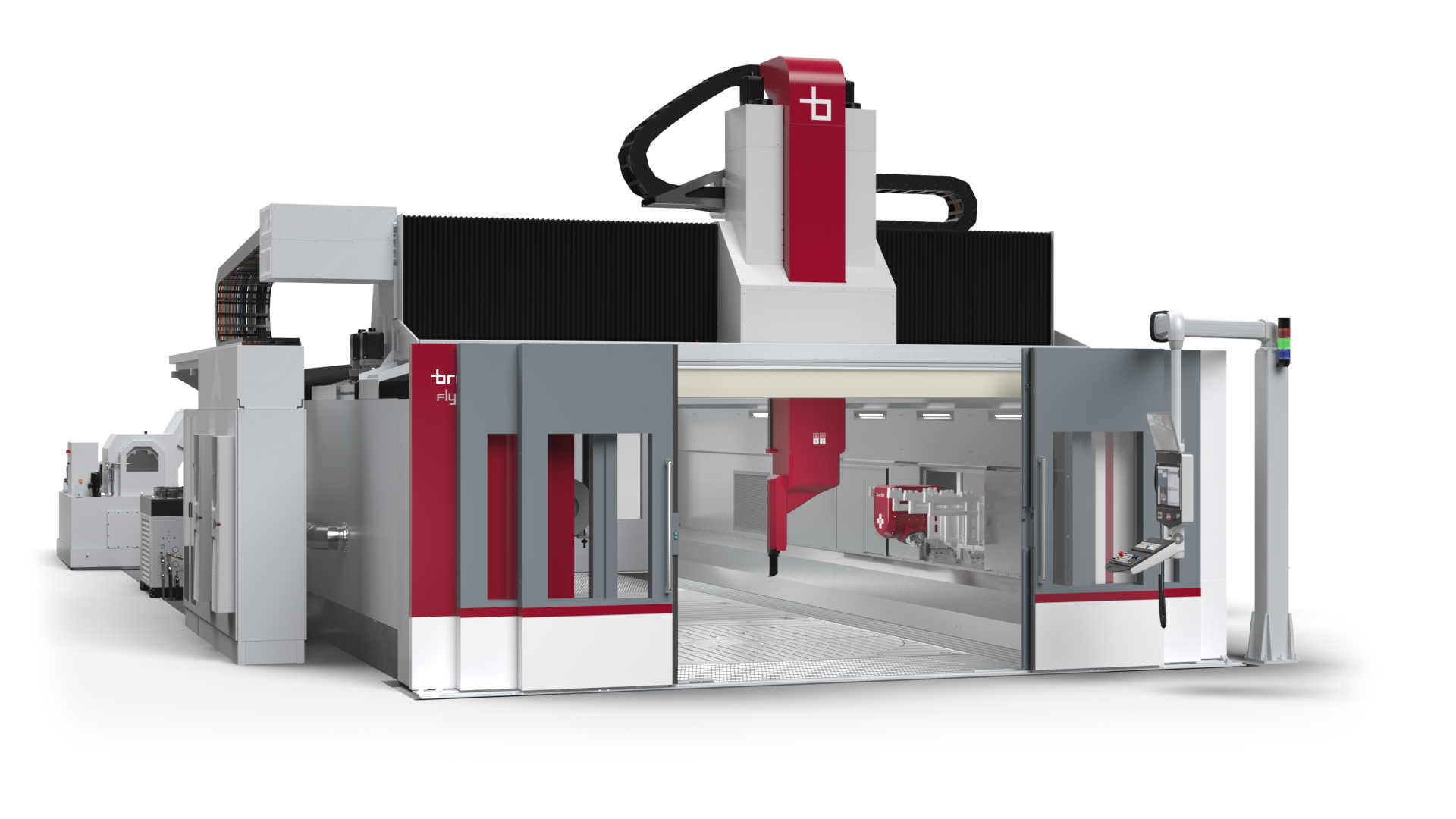

High power and high precision modular 5 axis vertical gantry machining centre

Concentrated force and accuracy on large dimensions to obtain the maximum performance in roughing, semi-finishing and finishing of workpieces in tough materials, steel, or lightweight alloy.

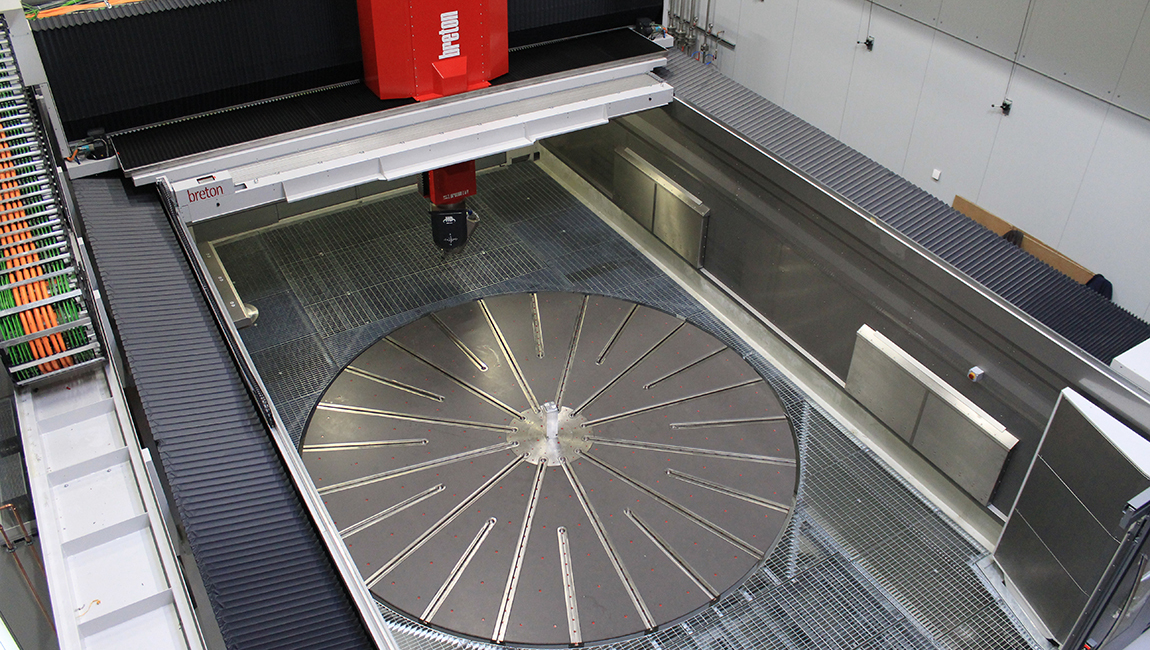

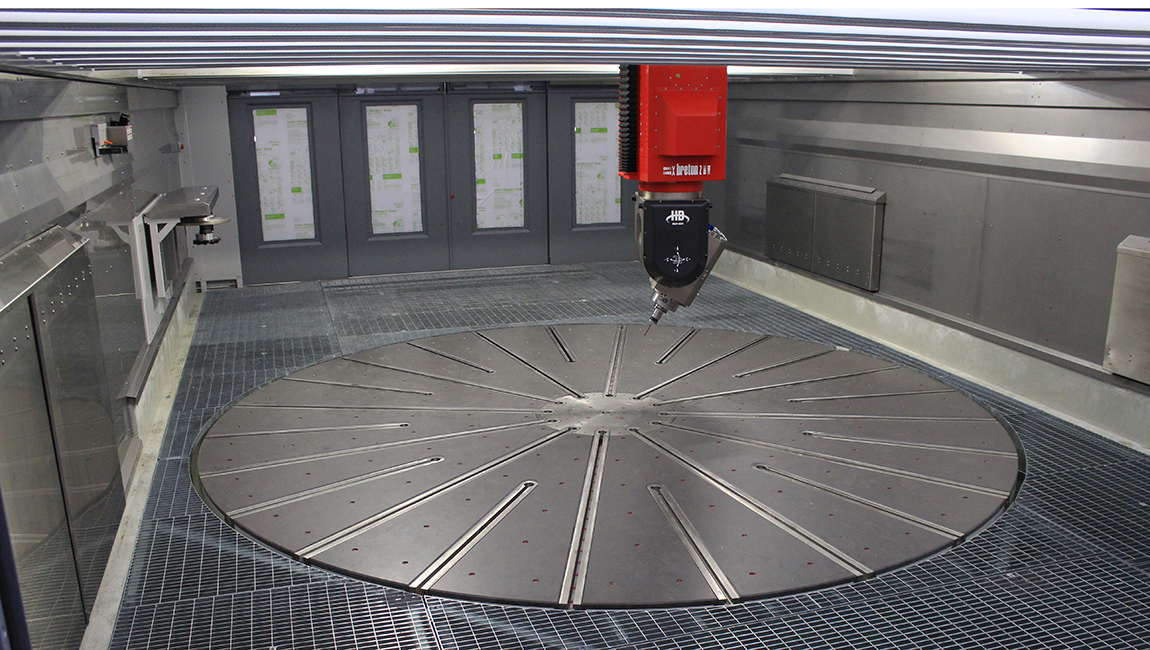

Available also in a milling and turning version (Flymill MT) that combines the functions of a vertical lathe with those of a 5 continuous axis milling machine, extending the range of possible applications with a single setup.

Breton Flymill

Reasons why

Power, speed and versatility in a single machining centre

Breton Flymill is the machining centre designed for companies operating with very large workpieces and, especially, for machining of tough materials that require high power and torque.

With Z axis strokes up to 1,500 mm, cross strokes up to 4,000 mm and longitudinal strokes up to 30,000 mm, Flymill is the machining centre for tough materials with the highest operating volume in the Breton range.

This machine is distinguished by its ability to combine milling and turning in a single set-up, exploiting the potential of the turning table and the automatic heads store to automatically switch from the powerful milling head to the boring bar head during the machining process.