Thanks to the double offset with respect to the RAM centre, Hornet allows machining of wider workpieces with the same X and Y linear strokes, both with the tool vertical and with the A axis at 90°.

The generous rotation of the A axis (-105° +135°) enables undercut machining, reducing the need to reposition the workpiece, with a consequent increase in precision and elimination of a second set-up phase.

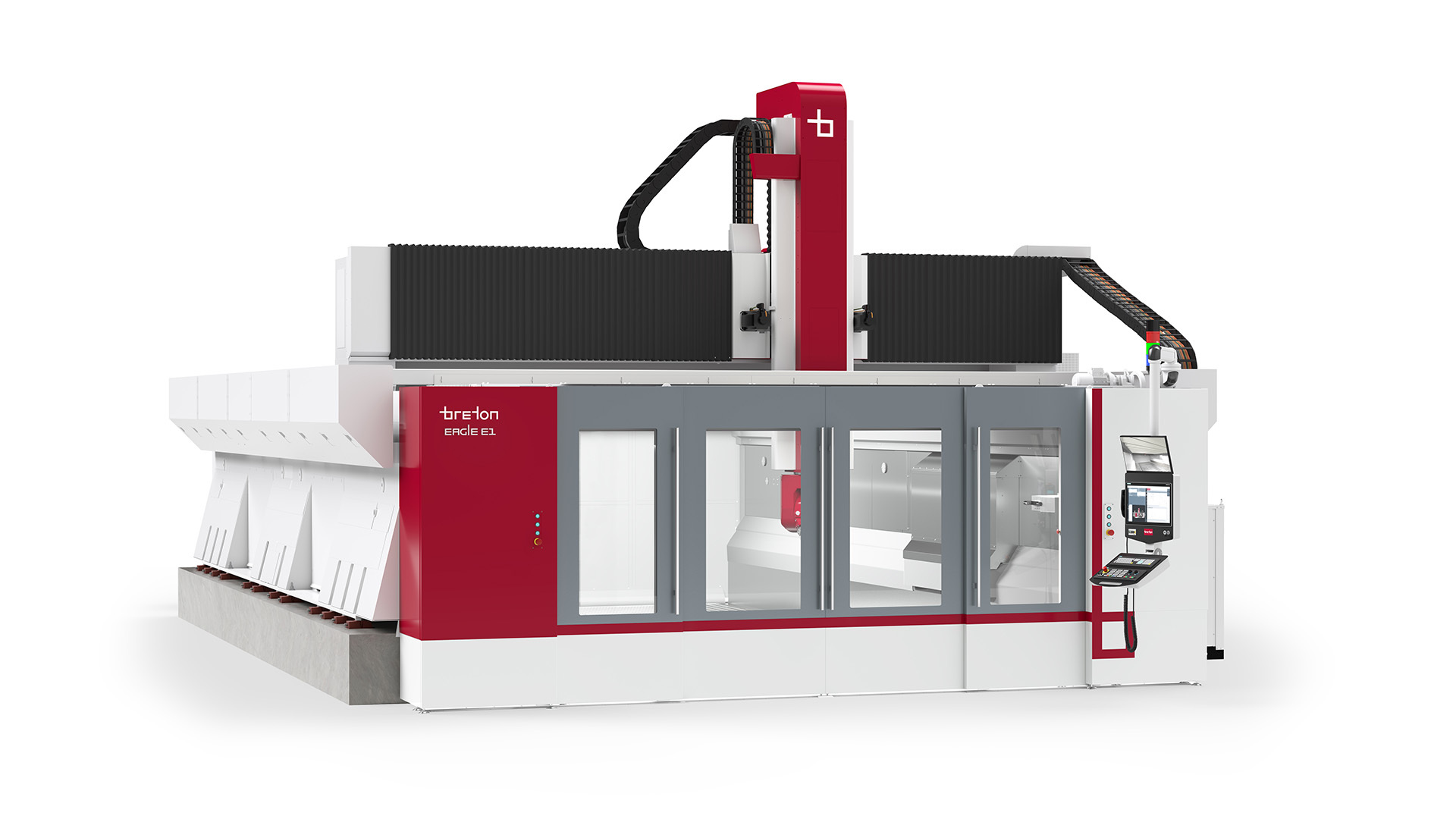

High dynamic 5-axis vertical gantry machining centre with modular structure

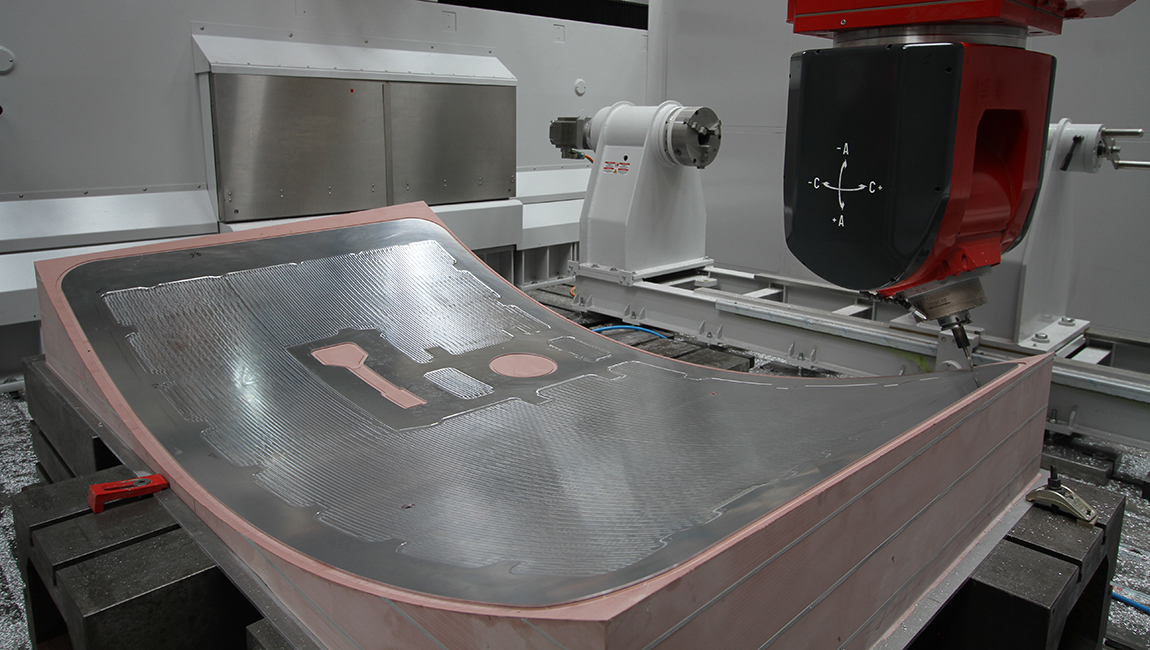

The wide range of structural combinations available makes it possible to create a bespoke configuration based on the required production volumes. The technical features make the machine ideal for high speed machining of parts with complex 3D shapes in lightweight alloy, resin, or composite materials.

Breton Eagle

Reasons why

Dynamics and power for machining composites and aluminium

The structure, entirely in arc welded steel and sized in accordance with FEA processes, not only reduces vibration and limits torsional stress, it also provides the necessary stiffness to ensure precision and repeatability through time. The slender structure and powerful brushless motors allow the machine to reach high speeds with quick acceleration: 70 m/min in X and Y, 50 m/min in Z (encoders on all linear axes) with acceleration of up to 4 m/s2.

This machining centre is ideal for companies making aluminium moulds and dies or patterns in resin, carbon fibre, and composites, always operating rapidly and with optimal precision.