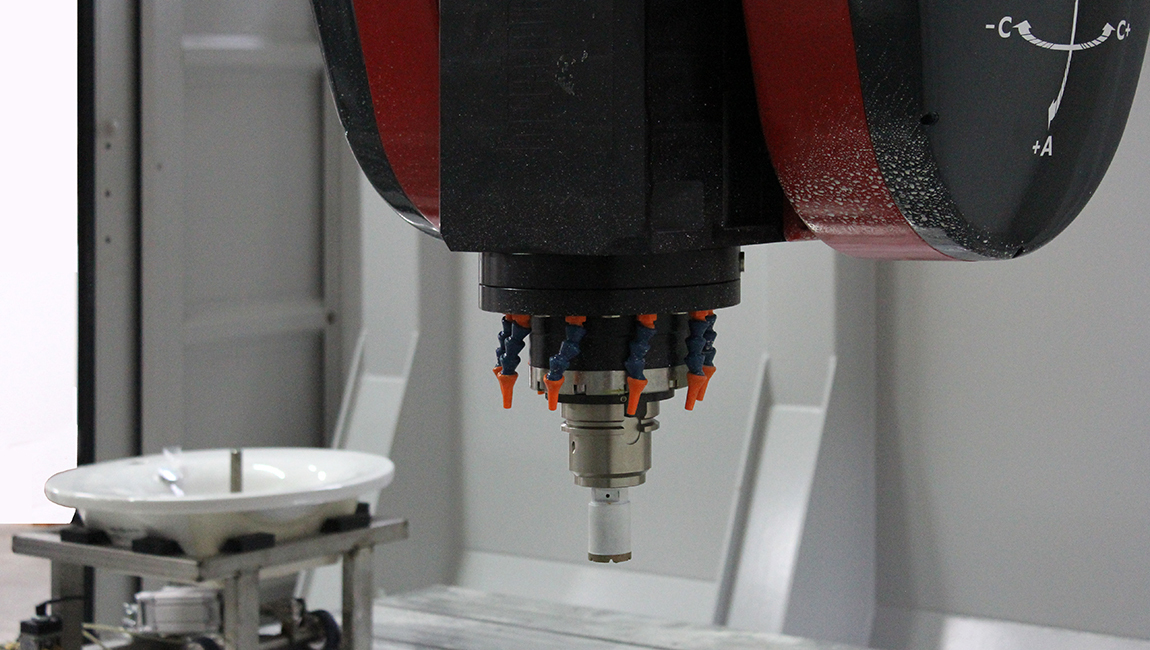

The bridge is moved by a rack and pinion gantry system driven by Siemens brushless motors of the latest generation in order to guarantee rapid and high precision movements.

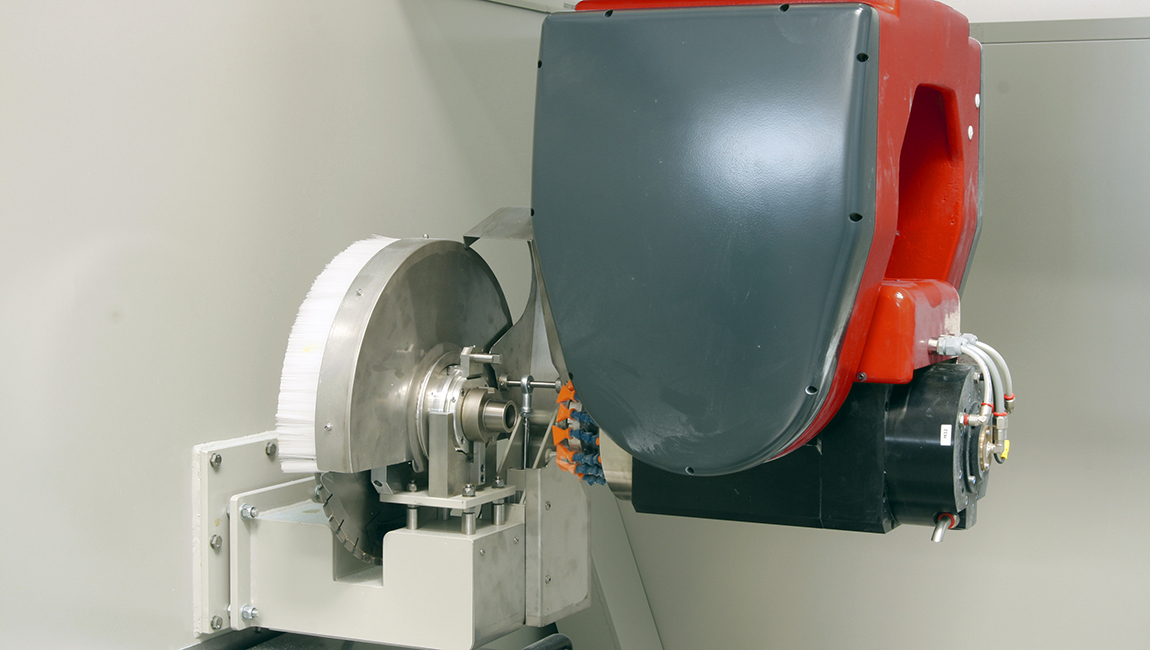

5-axis NC machining centre

Contour is a numerically controlled machining centre with five interpolated axes for production of items in marble, granite, mineral surface, and stone materials in general.

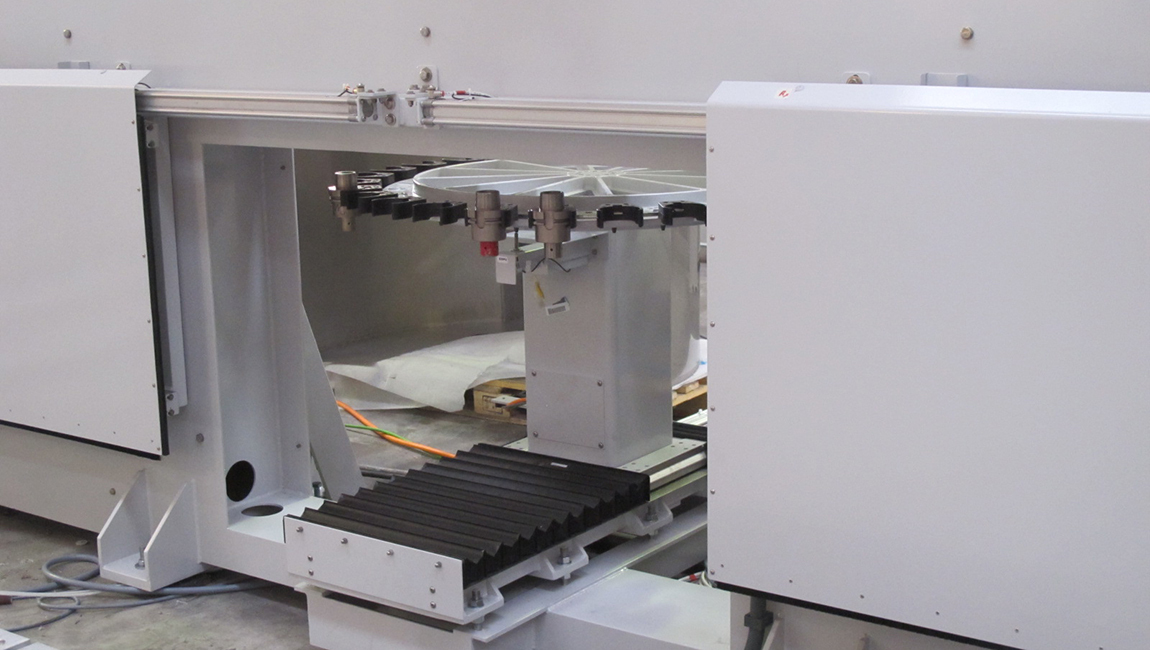

Thanks to its 700/1200 mm vertical stroke, Contour is ideal for architectural applications, funerary art, and deep slotting, allowing execution of complex and diversified machining processes.

Breton Contour

Reasons why

All in 1

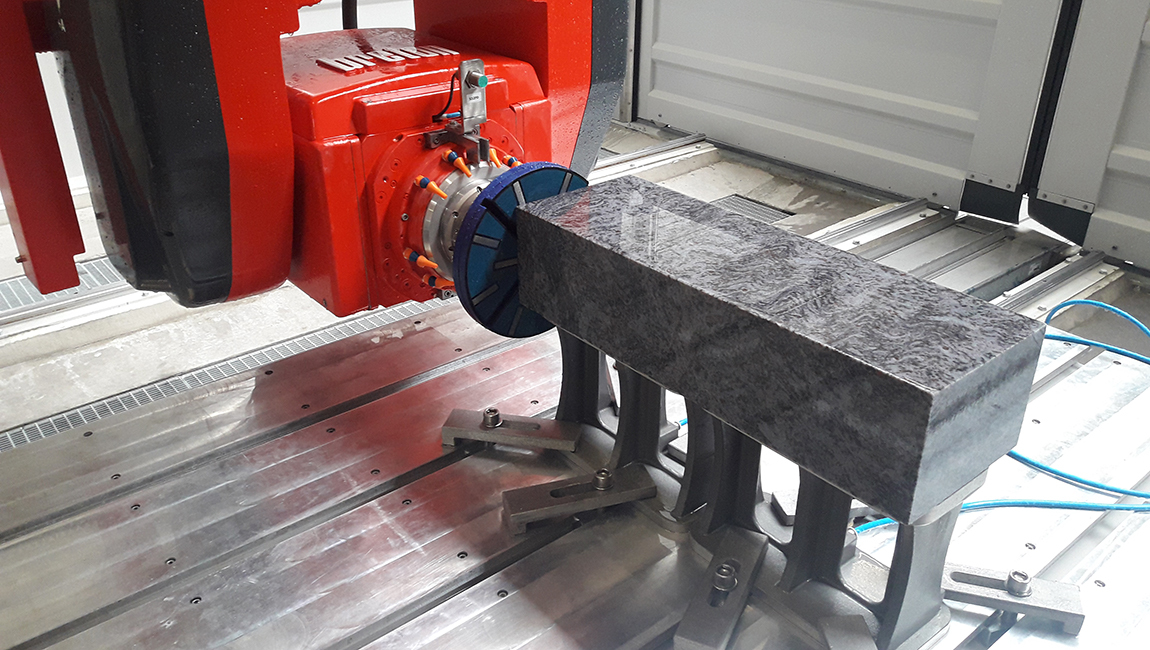

Breton Contour is a machining centre that combines the robustness and thrust required for roughing operations with the dynamics and precision needed for finishing. A stable and robust base that is also extremely dynamic, configurable with a broad range of components and accessories in order to handle entire machining processes in a large number of sectors.

Breton Contour is acclaimed for its reliability and precision, two aspects long associated with this model and that place it at the summit of the stoneworking industry in 5-axis machining work.

Contour can be used from contouring up to the creation of complex large size 3D statuary.

The machine is also particularly suitable for grinding and recovery of non-conforming parts after moulding, thus helping to reduce waste and maximise profits.

For more demanding clients the machine can be equipped with 3D scanners to read the shapes to be subsequently reproduced.

Breton Contour is available in 5 versions that are identified by the Z stroke and the torque of the installed spindle:

NC 700 (High speed) - NC700 HD (High torque) - NC1200 (High speed) - NC1200 HD (High torque) - NC1200 SHD (High Torque)

Tool holder configurations:

HSK-B80 - versions NC700/1200 e NC700/1200 HD

HSK-B100 - version NC1200 SHD

Materials

Processes

Industries

Finished products

Technologies

Numerical control

Spindle power

Patents

Spindle torque

Technological highlights

Other versions of Breton Contour

Version comparative table

| CONTOUR NC1200 | CONTOUR NC1200 HD | CONTOUR NC1200 SHD | |

|---|---|---|---|

"Z" axis travel (with "A" axis at 0°) | 1200 mm | 1200 mm | 1200 mm |

Spindle motor power (in S1 duty) | 16 kW | 18 kW | 30 kW |

Max. spindle rotation speed | 14500 rpm | 7500 rpm | 10000 rpm |

Tool holder | HSK-B80 | HSK-B80 | HSK-B100 |

"X" axis travel | 3600 mm | 3600 mm | 3500 mm |

"Y" axis travel | 2800 mm | 2800 mm | 2800 mm |

"X" axis max. displacement speed | 40000 mm/min | 40000 mm/min | 40000 mm/min |

"Y" axis max. displacement speed | 40000 mm/min | 40000 mm/min | 40000 mm/min |

"Z" axis max. displacement speed | 10000 mm/min | 10000 mm/min | 10000 mm/min |

"A" axis rotation | 0 - 115 ° | 0 - 110 ° | 0 - 115 ° |

"C" axis rotation | 400 ° | 400 ° | 400 ° |