Article

Story of BretonStone

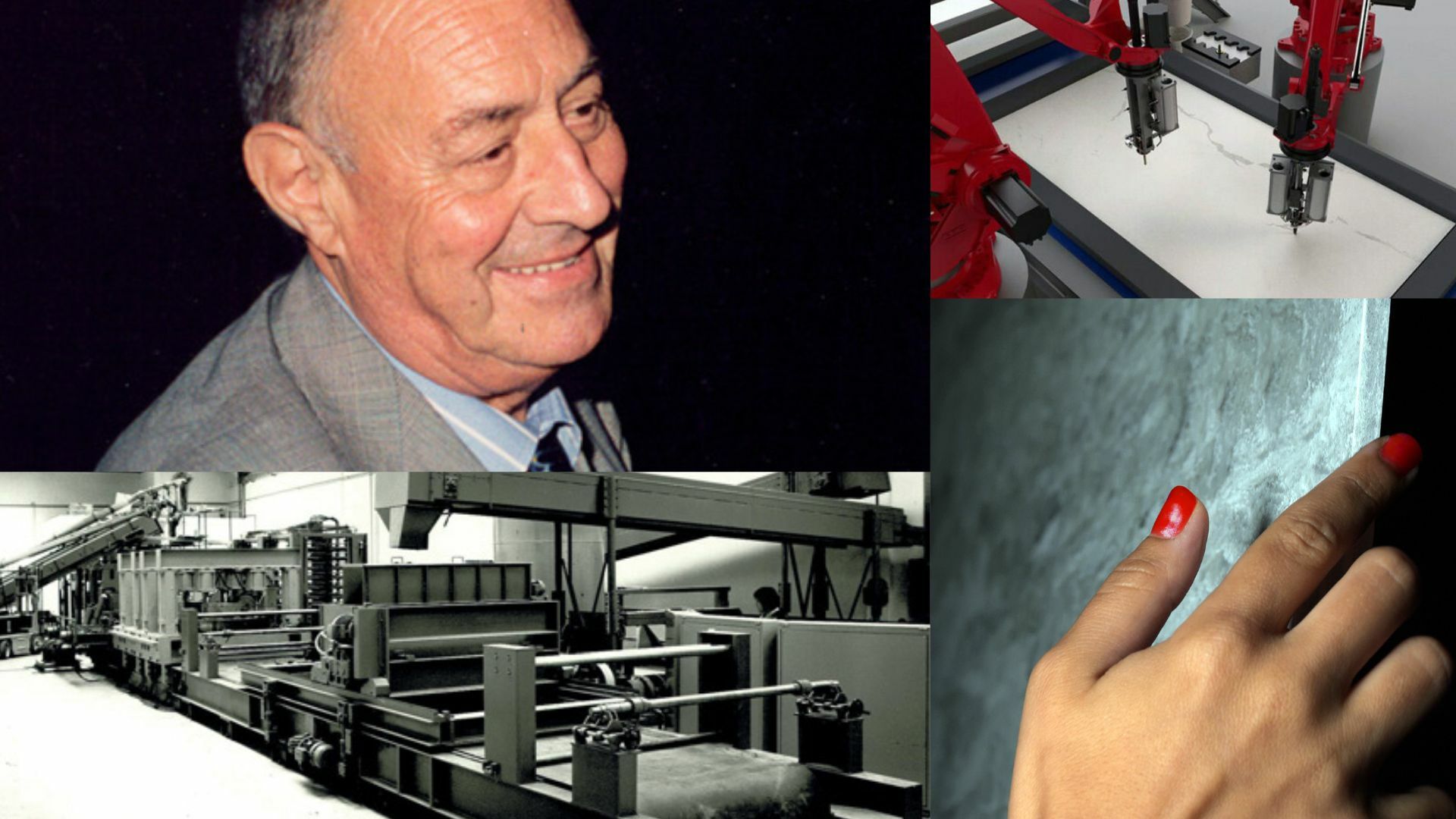

The story of a dream come true. The story of a man: Mr. Marcello Toncelli.

The beginnings

BretonStone® is the first mineral surface produced on an industrial scale in history. This material was born thanks to the brilliant intuition of Mr. Marcello Toncelli, Breton Founder.

The company developed an innovative technology for the production of blocks, composed of marble fragments and polyester resin. This technology allowed for the compaction of materials and their subsequent cutting into tiles.

It was the early 70s. The innovative idea was to develop a material that would change the stone paradigm. A different material. Similar to granite, with small aggregates that give the possibility to produce slabs instead of blocks. In this phase, the difficulties and trials were countless and challenging. First of all, the development of compaction technology for Vibro-compression under vacuum.

The solution? Mr. Toncelli had the idea to vacuum the mixture. To do this, he chose to use a hot water bottle. He inserted the mixture into the bottle, screwed the cap, and beat it with an axis and a hammer for the compaction. He put everything in the oven to catalyze and, once he cut the rubber, got the first BretonStone® tile!

At that point, the real challenge became getting this technology on an industrial scale.

The first plants

After a few years of research and experimentation, Mr. Toncelli and his team developed the first BretonStone® plant. The plant allowed the production of 125x125 cm slabs and was sold for the first time in 1979, in Tunisia.

In the same phase, other companies in Venezuela, Italy, Singapore, Spain, and the United States purchased the plant. The initial version of BretonStone® featured a limitation on its potential due to the stone aggregates employed in the process. In fact, the material had an aesthetic appearance similar to that of granite but with the physical characteristics of marble. So, it was necessary to use harder materials to reach granite hardness. An example? Quartz.

From that moment, a second-generation BretonStone® was born. A material obtainable through hard aggregates (silica sand, quartz, and granite).The new BretonStone® had a higher aesthetic yield than granite, greater strength, and a total lack of absorption. From that moment, BretonStone® producers decided to use mainly siliceous sand or quartz.

Caesarstone and Cosentino

The spread of technology continued. Caesarstone (Israel) was the first Company to start a new-generation BretonStone® plant. It was 1987. That choice determined the success of this Company. Today, Caesarstone is one of the largest companies in the industry, listed on the NASDAQ in New York and with 6 BretonStone® operating plants.

In 1989, Cosentino (Spain) installed a plant for employing its quarry waste. The Company decided to convert to the quartz by creating the Silestone brand. This choice led to its exponential growth and, thanks to an effective marketing action, the affirmation in the US market. Today, Cosentino is the largest global manufacturer of BretonStone® with 14 operating plants.

From that moment, many companies decided to invest in this technology. BretonStone® became the reference point in the world of mineral surfaces.

The evolution of aesthetics and sizes

The size range of BretonStone slabs has expanded over time, reaching a maximum size of 210x360cm (SuperJumbo). The thickness range has also expanded over the years, reaching a range from 7 to 30 mm.

The aesthetic effects of the slabs have evolved strongly over time: from the granite effect to monochrome, veined marble, and the ultra-exotic Kreos®.

BretonStone® producers created a world of beautiful aesthetic effects, thanks to the introduction of colored glass, crystals, mirrors, semi-precious stones, and much more.

The global success

Today, BretonStone is a large family that includes all the products manufactured by the various companies that produce and distribute it worldwide:

Santa Margherita, Caesarstone, Technistone, Daltile, Cosentino, Cambria, Seieffe, Quarella, Silicalia, AKG, Dupont, Vicostone, Technistone, Diresco, Pokarna, Quartzforms, LG, Belenco, Hyundai, Marudhar and many others.

Thanks to these industrial realities, Bretonstone® represents a widely used and appreciated material on a global scale. An amazing choice to build airports (Dubai, London Heathrow, Amsterdam), shops (Giorgio Armani in New York, Prada in Dubai, Fendi, Ferrè, Diesel, Swatch, Montblanc), commercial centers (Gallerie Lafayette, Sunset Mall Dubai), hotels (Burj Al Arab in Dubai), schools, hospitals, residential buildings, churches, mosques; from Paris to the USA, from the Arab Emirates to China, Malaysia, Russia, Singapore, Senegal, Brazil, and Australia.

Everywhere in the world, there is a bit of Italy and the one who thought, wanted, created, and spread this innovative material, which allows all architects to turn dreams into reality: Mr. Marcello Toncelli.

Milestones

Explore the glorious history and major evolutionary steps of BretonStone® system