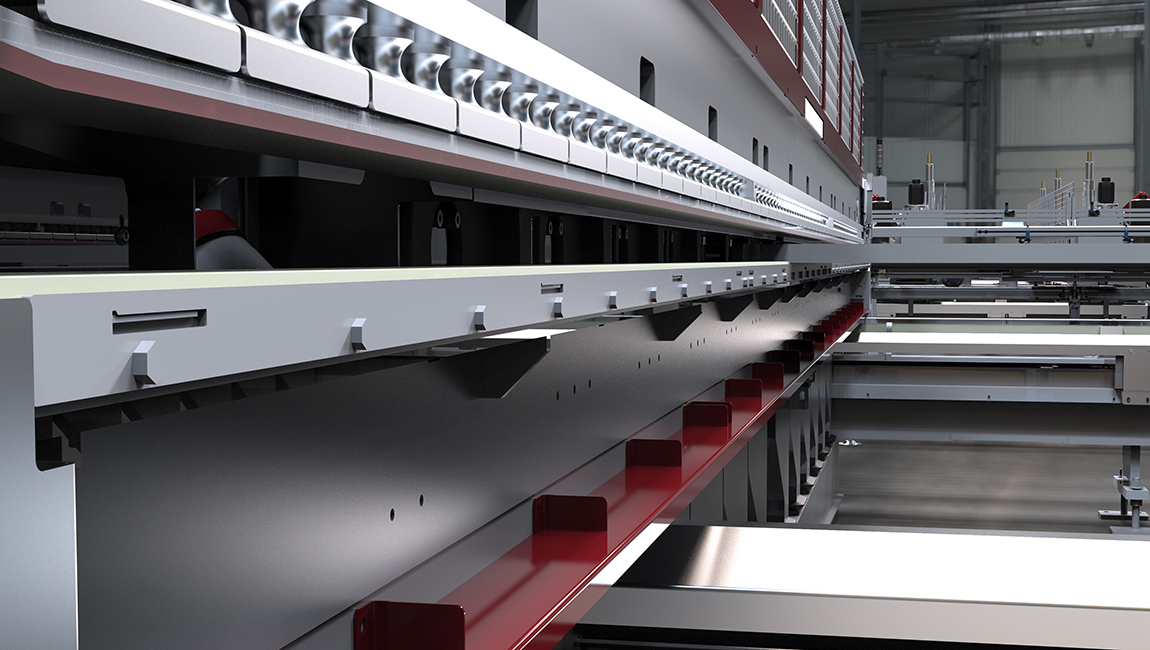

HSC spindles are designed to reach rotation speeds of up to 4,900 rpm. Considering the same material feed speed, the tool is capable of a higher number of revolutions. This makes it possible to reduce the volume of material to be removed in each revolution, reducing the size of machining dust and the risk of chipping damage.

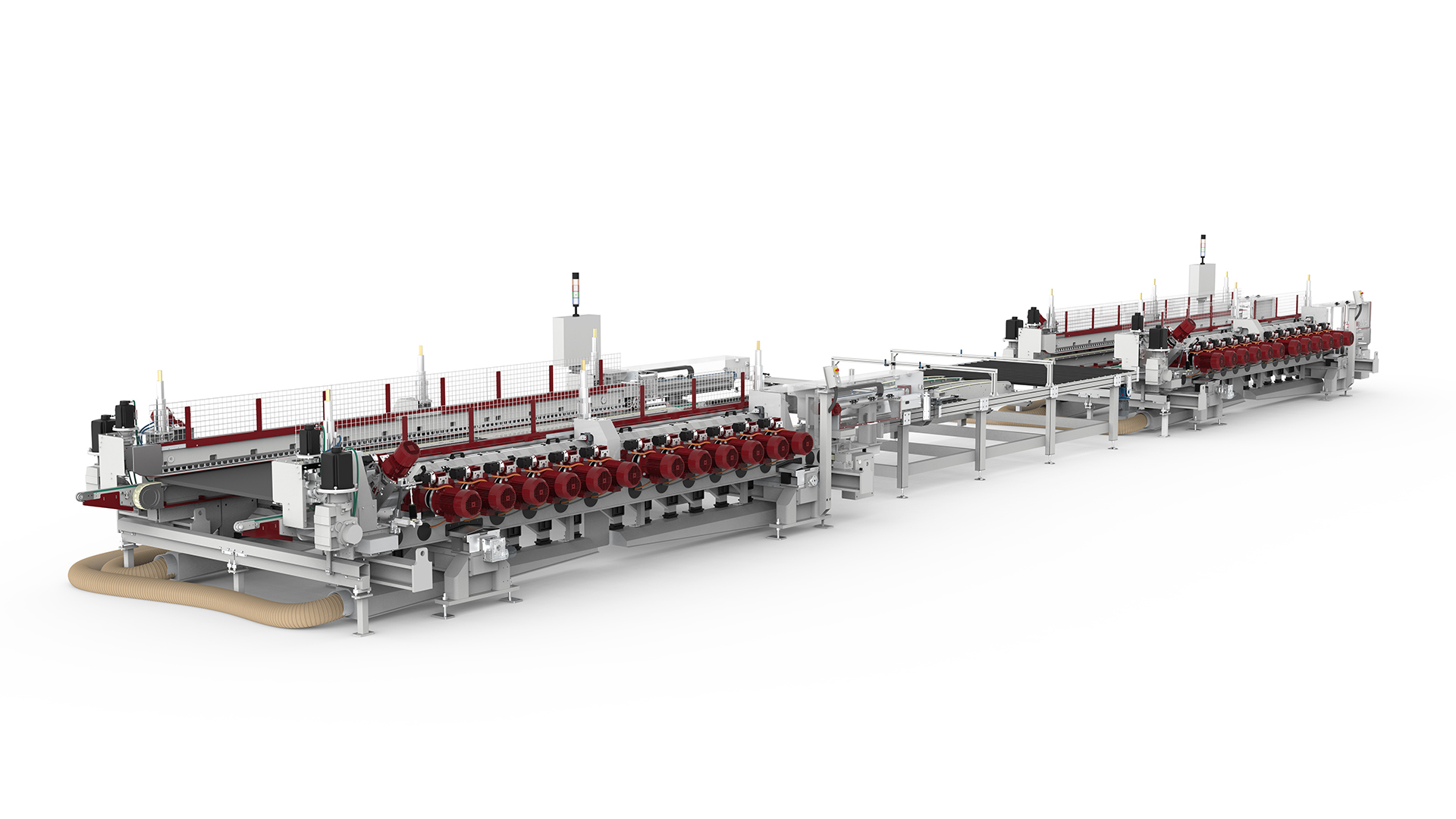

Automatic dry squaring machine for ceramic tiles and slabs

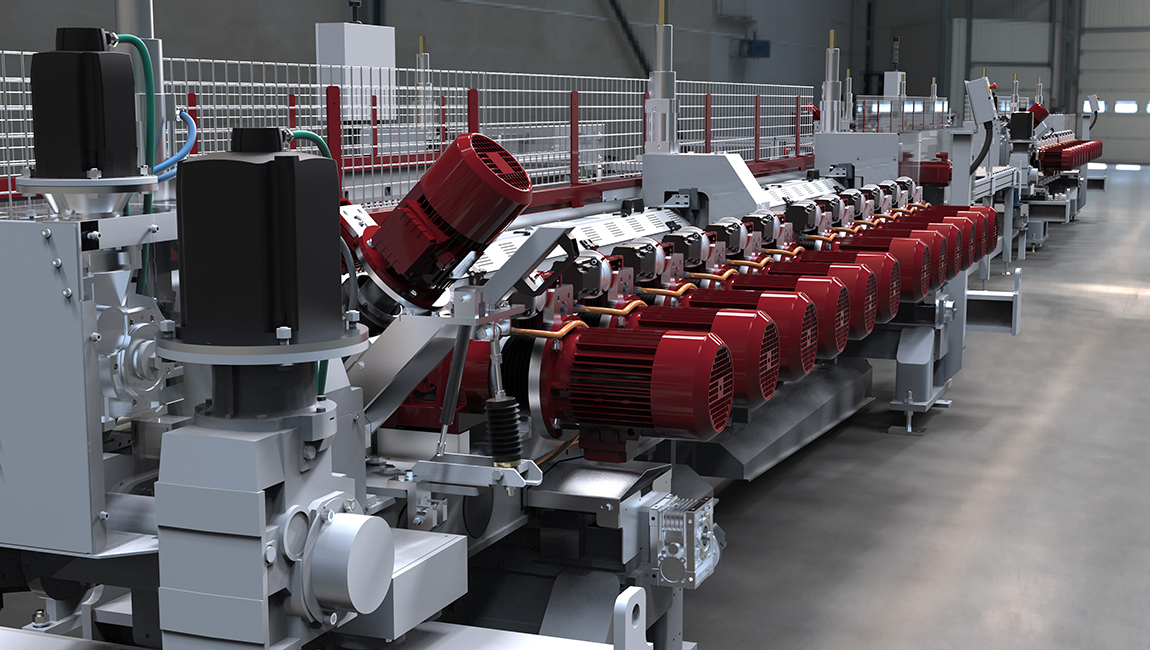

The high rotation speed of the gauging spindles, its structural solidity and reduced maintenance costs make Ghibli the ideal solution for rectification of ceramic tiles and slabs.

Breton Ghibli

Reasons why

Automations that boost productivity

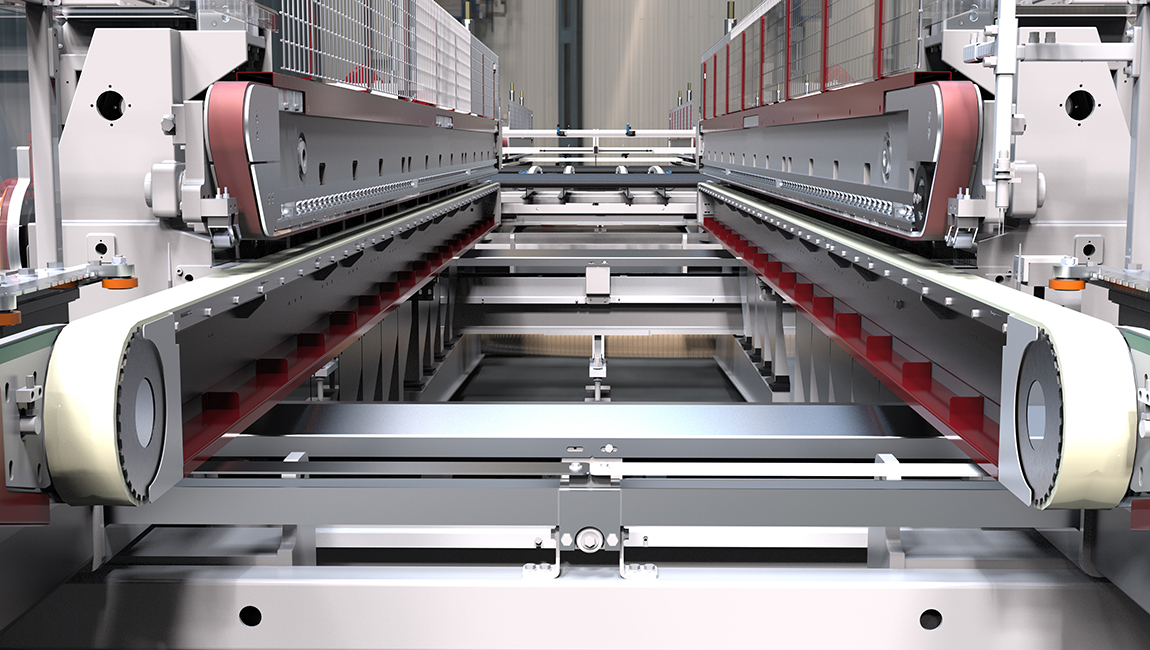

Dry squaring machine for ceramic slabs and tiles, able to mount up to 12 high rotation speed gauging spindles and one upper chamfering spindle for each bench. Thanks to the presence of inverters, the rotation speed of the grinding wheels can be set at the optimal value.

The automatic gauging tools positioning system allows removal cone set-up operations to be performed in a matter of minutes. During start-up, the combined action of the precision lasers makes it possible to read the position of each grinding wheel automatically, thereby creating a balanced removal cone resulting in longer tool life.

Ghibli's evolved software makes it possible to manage all the machining parameters and generate customised recipes to reduce line set-up times. Ghibli can also be supplied with the patented new Iuppiter control system, capable of correcting the positions of the single gauging spindles automatically, optimising material removal and grinding wheel wear.