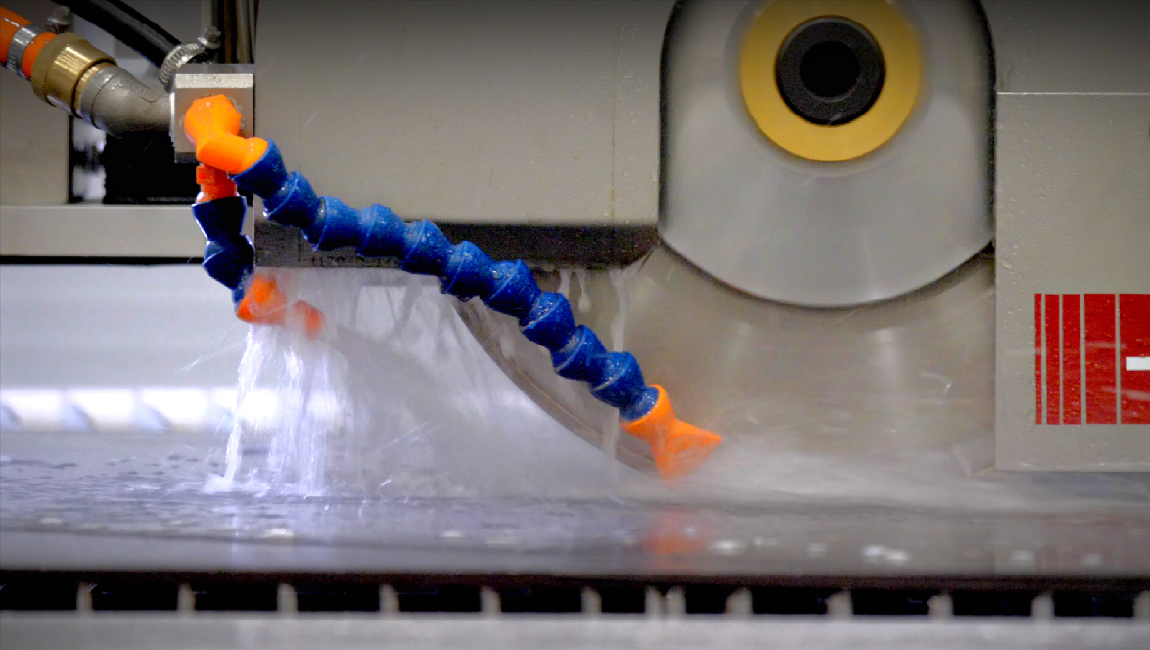

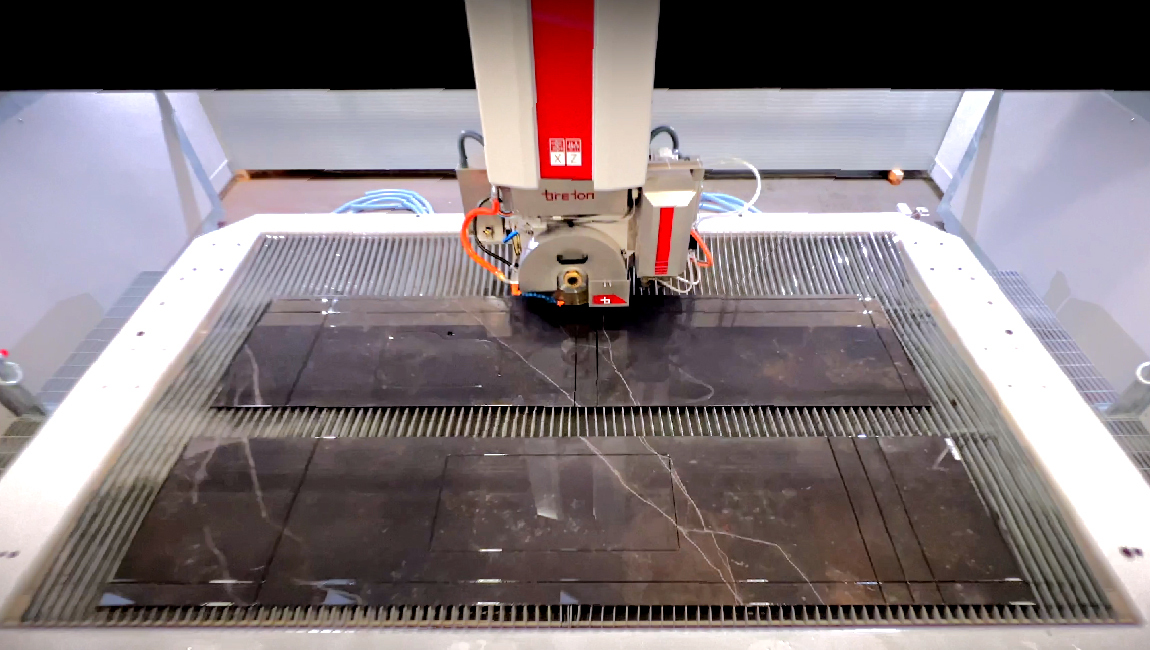

Double waterjet with automatic nozzle adjustment.

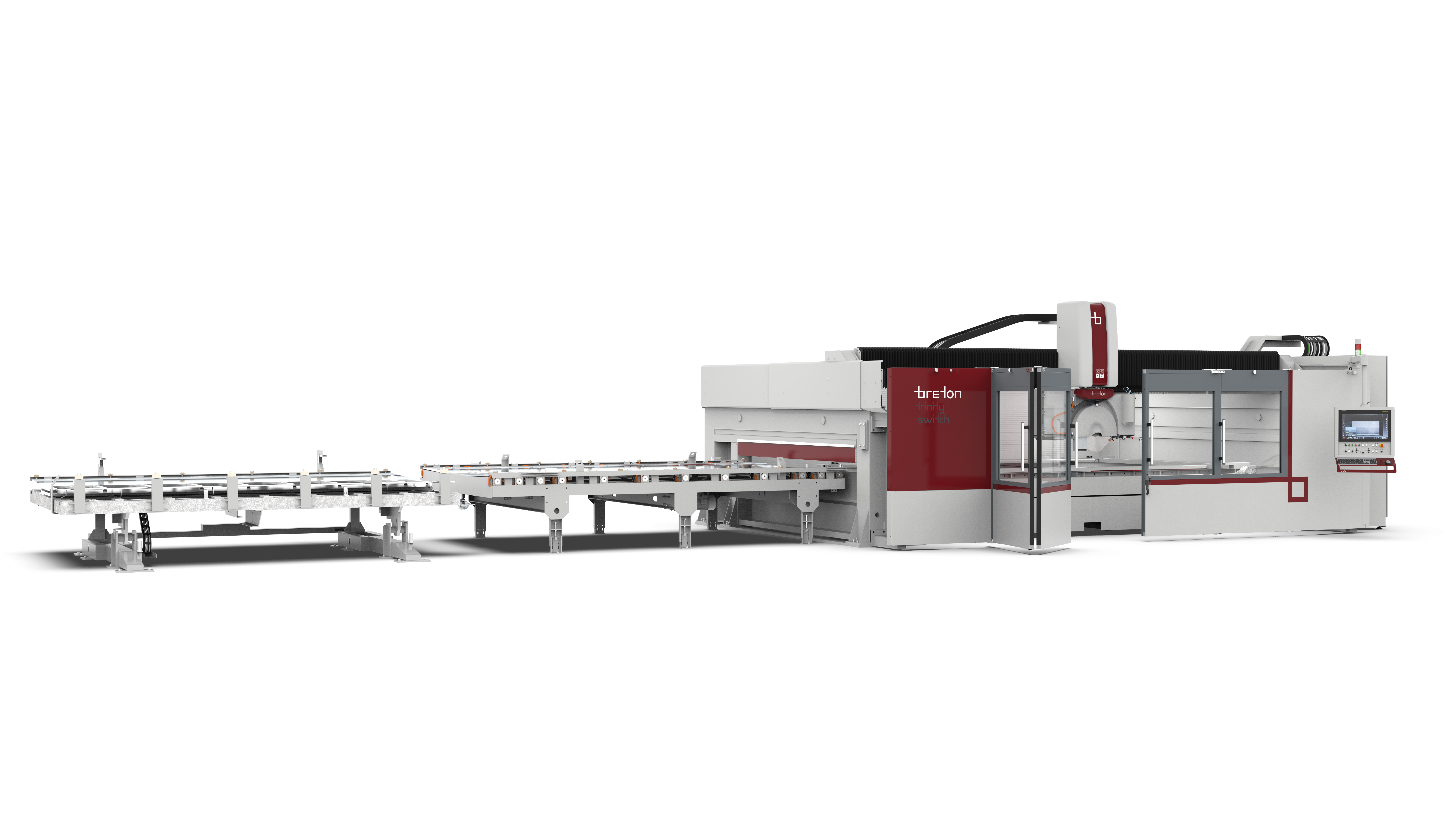

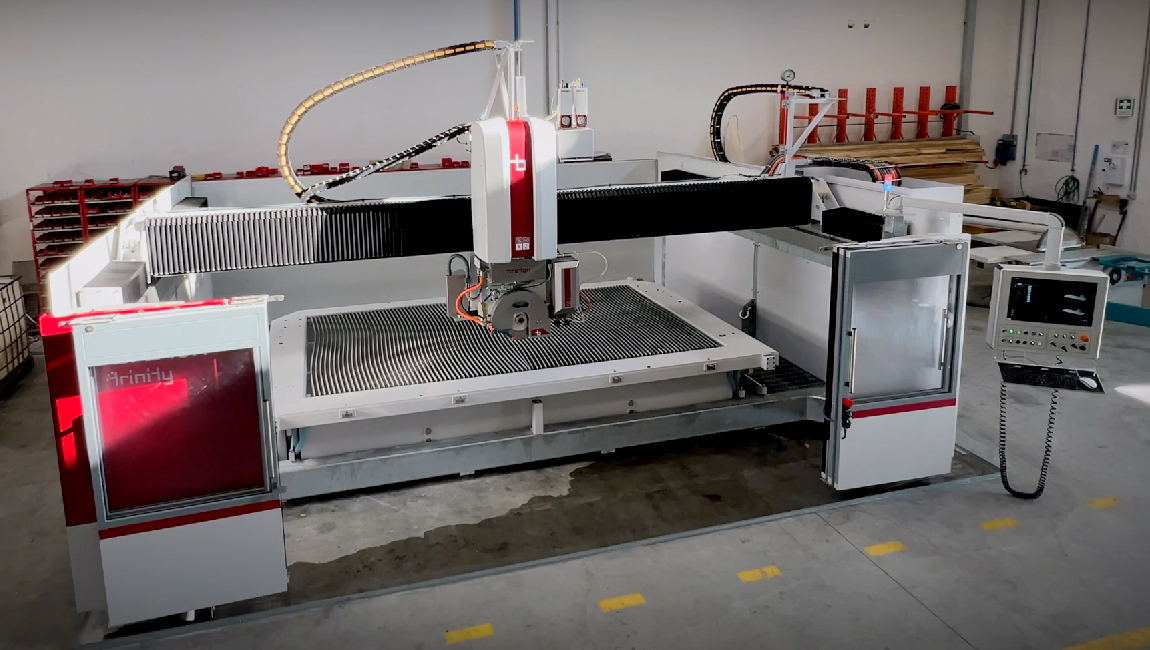

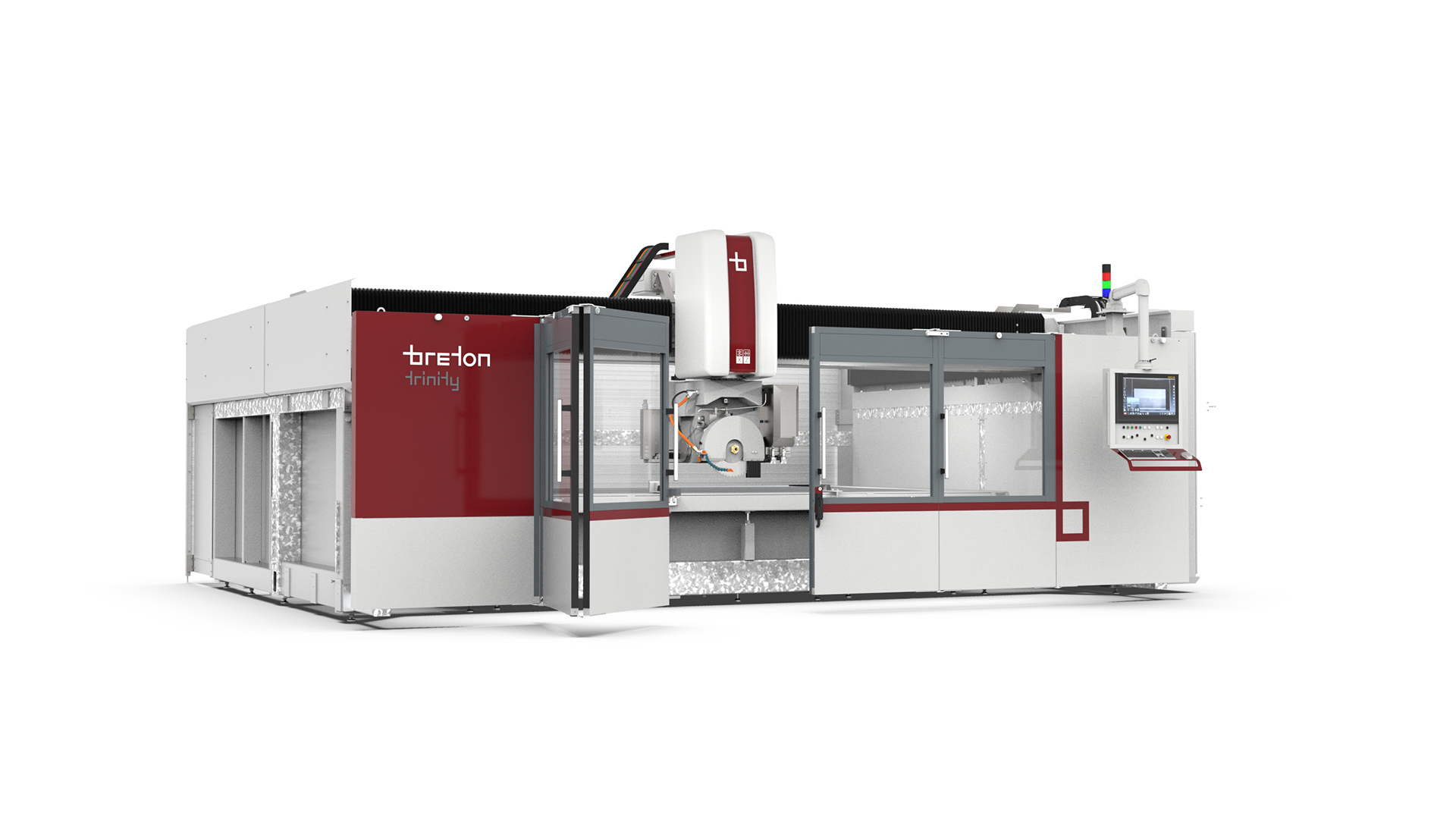

Combined saw and waterjet cutting centre

The possibility of combining saw and waterjet cutting, together with tools such as vacuum cups, camera on the bridge and tilting table, make the Trinity, evolution of the Breton Combi, the most advanced cutting center for the creation of kitchen worktops, vanity tops and claddings.

Breton Trinity

Reasons why

The revolution in ceramic slab cutting

Breton Trinity is more than a machine; it is a process, a technology designed specifically for processing ceramic materials, but it also adapts brilliantly to other products.

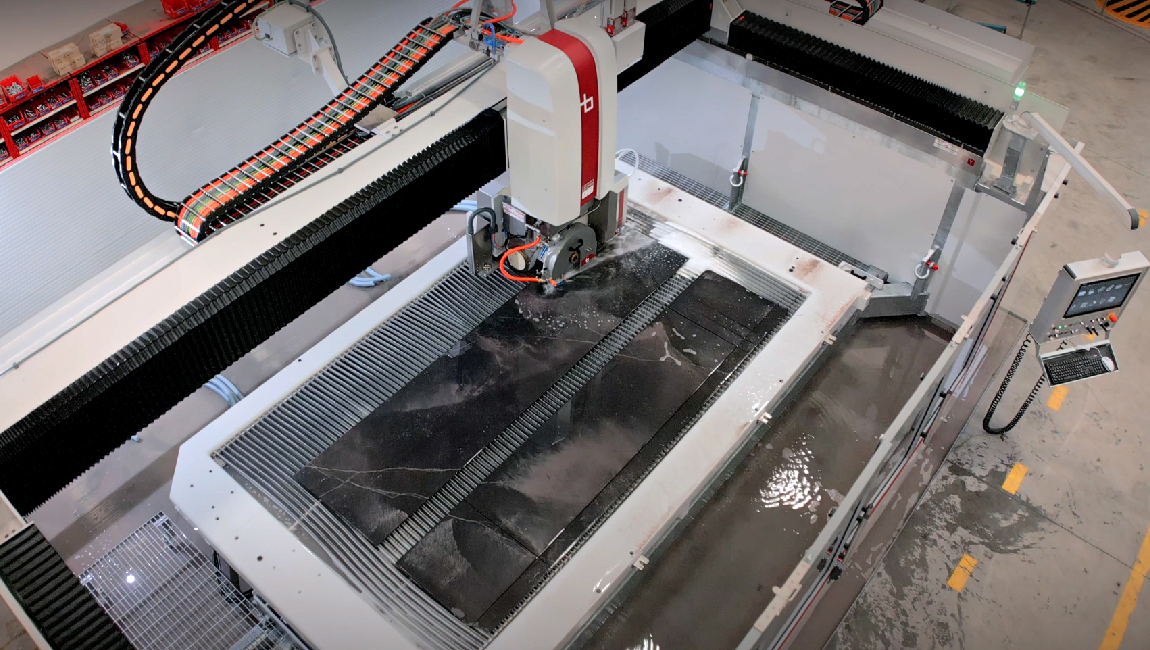

Trinity's strength is that it allows simultaneous saw and double waterjet cutting or waterjet-only cutting without the need to move the slab and, depending on the operation it has to perform, it chooses the best technology in terms of efficiency. Therefore, when possible, Trinity will opt for the more economical saw+waterjet cutting, while switching to pure waterjet technology in all other cases. This will minimize waste and get the job done in less time, and consequently, at the lowest cost. Trinity was designed to meet two main needs:

1. operate with the slabs placed directly on the metal grid, without interposing the sacrificial support, thus avoiding the costs and downtime associated with periodic replacement of the support;

2. cutting ceramic slabs, as well as other stone materials, with high feed rates and low operating costs while avoiding chipping and cracking.

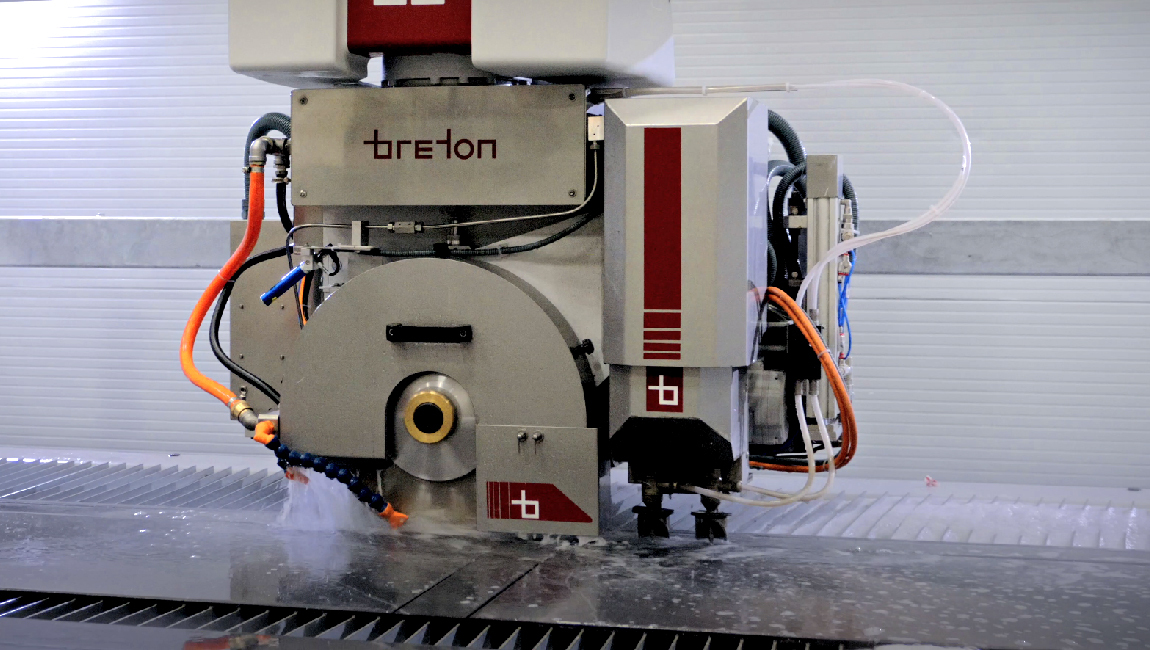

This machine represents the perfect fusion of two technologies, combining the maximum removal capacity of the saw with the cutting smoothness of the double waterjet nozzle.

The saw removes the material without risk of breakage, ensuring the integrity of the plate thanks to a solid plinth at the base. Afterwards, the dual waterjet nozzle intervenes with precision, removing the remaining part quickly and without stressing the material.

Inclined planes can also be created without having to mill the surface of the workpiece, but only by exploiting the variable inclination waterjet cutting with continuous probing by the Miterwave Touch.

Important advantages for increased productivity also come from the vacuum cups on the spindle, which allow workpieces to be moved in order to use saw cutting.

In addition, the installation of the Rocket Tool system, an additional electrospindle that can reach up to 14,000 rpm on which finger bits or drill tools can be mounted, can perform through or blind bores, milling and rebating.

Trinity increases production capacity by almost three times compared to waterjet and reduces slab breakage to almost zero, benefiting both the processor and the raw material producer.

Materials

Processes

Industries

Finished products

Numerical control

Technologies

Technological highlights

Other versions of Breton Trinity

Version comparative table

| Breton Trinity | Breton Trinity | Single Waterjet | Breton Trinity Switch | |

|---|---|---|---|

Dimensions of the worktop (length) | 3650 mm | 3650 mm | 3650 mm |

Dimensions of the worktop (width) | 2150 mm | 2150 mm | 2150 mm |

Max. diameter of the saw blade combined with waterjet | 400 mm | 400 mm | 400 mm |

Max. cutting thickness (with Ø 400 mm saw blade) | 80 mm | 80 mm | 80 mm |

"X" axis travel | 4600 mm | 4600 mm | 4600 mm |

"Y" axis travel | 3050 mm | 3050 mm | 3050 mm |

"Z" axis travel | 320 mm | 320 mm | 320 mm |

"C" axis rotation | 380 ° | 380 ° | 380 ° |

"A" axis rotation | 0 - 58 ° | 0 - 58 ° | 0 - 58 ° |

Spindle motor power (in S1 duty) | 18 kW | 18 kW | 18 kW |

Spindle motor power (in S6 duty) | 22 kW | 22 kW | 22 kW |

Mass | 12000 kg | 12000 kg | 18000 kg |

Overall dimensions (length) | 8100 mm | 8100 mm | 17600 mm |

Overall dimensions (width) | 6080 mm | 6080 mm | 6080 mm |

Overall dimensions (height) | 5500 mm | 5500 mm | 5500 mm |